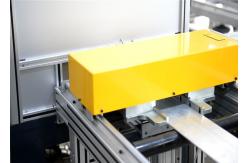

High Accuracy One Time Molding Busbar Processing Machine

|

|

High Accuracy One Time Molding Busbar Processing Machine

Features

Application

This processor is suitable for making large electric cabinet ,power distribution cabinets ,switch cabinets and power transmission and distribution construction engineering construction site use.Suitable for transmission and distribution in a large workshop and site work, construction, and power distribution cabinets and switch cabinets, etc.

Equipment data on busbar conductor multifunctional processing machine

Function introduction

By busbar conductor multifunctional processing machine, operator will input values such as length, width, piler position, quantity and etc. to initiate automatic working procedures including ends punching, piler opening, piler punching and etc..

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 400mm Busbar Processing Machine 1800mm Busbar Processing Machine 400 KN Busduct Production Line | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Automatic Copper Aluminum Cnc Busbar Processing Machine Shearing Bendin Punching |

|

CNC cutting bending punching Busbar Processing Machine |

|

Hydraulic Busbar Fabrication Machine Copper Piler Punching |

|

High Precision 31.5MPa Hydraulic Busbar Fabrication Machine |

|

Busbar Punching Bending Cutting Machine For Copper Aluminum Bar |

|

Outlet phase stab Punching Multi Functional Busbar Processing Machine |