|

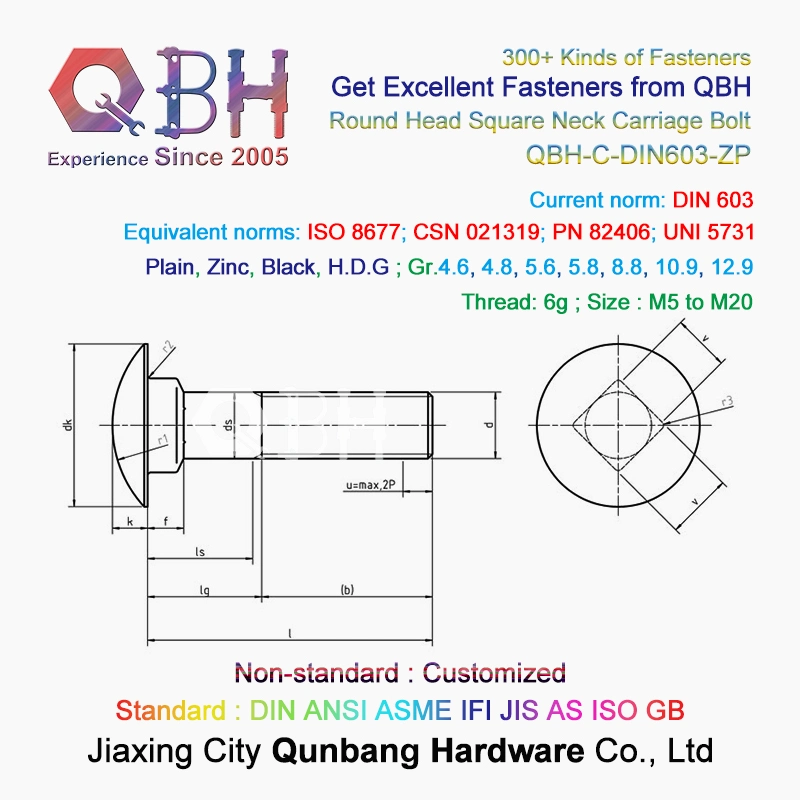

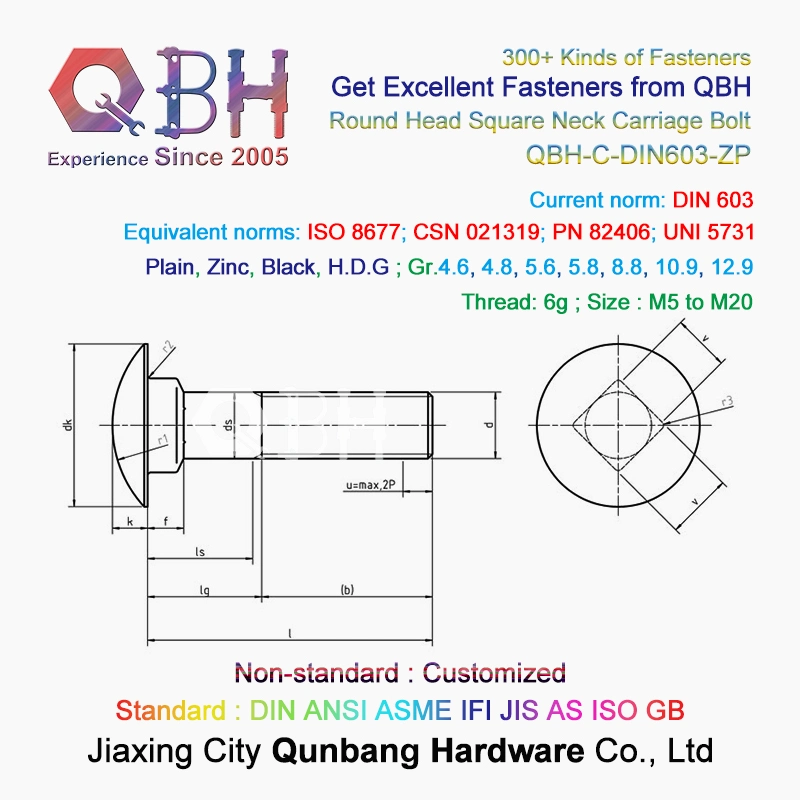

Product Description | Products name | Round Head Square Neck Carriage Bolt DIN603 Carbon Steel WZP | | Standard: | DIN,ASTM/ANSI JIS EN ISO,AS,GB | | Model No. | QBH-C-DIN603-ZP,

QBH-C-DIN603-HDG | | Supplier | QBH | | Material | Stainless Steel: SS201, SS303, SS304, SS316,SS316L,SS904L,F593 | | Steel Grade: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A,307B,A325,A394,A490,A449, | | Finishing | Zinc(Yellow,White,Blue,Black),Hop Dip Galvanized(HDG),Black Oxide,

Geomet,Dacroment,anodization,Nickel plated,Zinc-Nickel plated | Production

Process | M2-M24:Cold Froging,M24-M100 Hot Forging,

Machining and CNC for Customized fastener | Customized Products

Lead time | Busy season:15-30days,Slack seaon:10-15days | | Stock Products | Steel:4.8Grade DIN6923,8.8Grade 10.9Grade of GB5783 and GB5782

Stainless steel: All DIN Standard stainless steel Bolt | | Free Samples for standard fastener |  Legend: b - length of the thread (at least)

l - length of bolt

d - the nominal diameter of the thread

k - head height

ds - diameter of the screw shank

dk - head diameter

f - height squared

v - width of the square

r1 - Head radius

lg - length of the shank to thread

ls - length of the shank to the start of the thread Makings: Steel: 4.8,5.8,8.8

Stainless: A2, A4

Thread: 6g Notes: Table according to DIN 603: | Thread d | M5 | M6 | M8 | M10 | M12 | M16 | M20 | | Product Name | DIN 603 Square Neck Round Head Carriage Bolt | | Supplier | QBH | | P | 0,8 | 1 | 1,25 | 1,5 | 1,75 | 2 | 2,5 | | b | l < 125mm | 16 | 18 | 22 | 26 | 30 | 38 | 46 | | 125 < l < 200mm | 22 | 24 | 28 | 32 | 36 | 44 | 52 | | l > 200mm | - | - | 41 | 45 | 49 | 57 | 65 | | dk | max. | 13,55 | 16,55 | 20,65 | 24,65 | 30,65 | 38,8 | 46,8 | | min. | 12,45 | 15,45 | 19,35 | 23,35 | 29,35 | 37,2 | 45,2 | | ds | max. | 5 | 6 | 8 | 10 | 12 | 16 | 20 | | min. | 4,52 | 5,52 | 7,42 | 9,42 | 11,3 | 15,3 | 19,16 | | f | max. | 4,1 | 4,6 | 5,6 | 6,6 | 8,75 | 12,9 | 15,9 | | min. | 2,9 | 3,4 | 4,4 | 5,4 | 7,25 | 11,1 | 14,1 | | k | max. | 3,3 | 3,88 | 4,88 | 5,38 | 6,95 | 8,95 | 11,05 | | min. | 2,7 | 3,12 | 4,12 | 4,62 | 6,05 | 8,05 | 9,95 | | r1 | approx. | 10,7 | 12,6 | 16 | 19,2 | 24,1 | 29,3 | 33,9 | | r2 | max. | 0,5 | 0,5 | 0,5 | 0,5 | 1 | 1 | 1 | | r3 | max. | 0,75 | 0,9 | 1,2 | 1,5 | 1,8 | 2,4 | 3 | | v | max. | 5,48 | 6,48 | 8,58 | 10,58 | 12,7 | 16,7 | 20,84 | | min. | 4,52 | 5,52 | 7,42 | 9,42 | 11,3 | 15,3 | 19,16 |

Dimensions

| Nom. Dia. (d) | M6 | M8 | M10 | M12 | M16 | M20 | | Product Name | DIN 603 Square Neck Round Head Carriage Bolt | | Supplier | QBH | | Thread Pitch | 1 | 1.25 | 1.5 | 1.75 | 2 | 2.5 | | Thread Length (b) | L < 125mm | 18 | 22 | 26 | 30 | 38 | 46 | | 125-200mm | 24 | 28 | 32 | 36 | 44 | 52 | | L > 200mm | - | 41 | 45 | 49 | 57 | 65 | | dk | Max. | 16.55 | 20.65 | 24.65 | 30.65 | 38.8 | 46.8 | | f | Max. | 4.6 | 5.6 | 6.6 | 8.75 | 12.9 | 15.9 | | k | Max. | 3.88 | 4.88 | 5.38 | 6.95 | 8.95 | 11.05 | | v | Max. | 6.48 | 8.58 | 10.58 | 12.7 | 16.7 | 20.84 | | L | WEIGHT IN KG/1000 PCS | | 16 | 6.90 | | | | | | | 20 | 7.60 | 13.80 | 22.70 | | | | | 25 | 8.50 | 15.40 | 25.20 | | | | | 30 | 9.60 | 17.00 | 27.70 | 45.70 | | | | 35 | 10.70 | 19.00 | 30.20 | 49.40 | | | | 40 | 11.80 | 21.00 | 32.70 | 53.10 | | | | 45 | 12.90 | 23.00 | 35.80 | 56.80 | | | | 50 | 14.00 | 25.00 | 38.90 | 61.20 | 119.00 | | | 55 | 15.10 | 26.90 | 42.00 | 65.60 | 126.00 | | | 60 | 16.20 | 28.90 | 45.10 | 70.00 | 133.00 | | | 65 | 17.30 | 30.90 | 48.20 | 74.40 | 141.00 | | | 70 | 18.40 | 32.90 | 51.30 | 78.80 | 149.00 | 247.00 | | 80 | 20.60 | 36.80 | 57.50 | 87.00 | 165.00 | 272.00 | | 90 | 22.80 | 40.80 | 63.70 | 96.00 | 181.00 | 297.00 | | 100 | 25.00 | 44.80 | 69.90 | 105.00 | 197.00 | 322.00 | | 110 | 27.20 | 48.80 | 76.10 | 114.00 | 213.00 | 347.00 | | 120 | 29.40 | 52.80 | 82.30 | 123.00 | 229.00 | 372.00 | | 130 | 31.60 | 56.80 | 88.50 | 132.00 | 245.00 | 397.00 | | 140 | 32.80 | 60.80 | 95.00 | 141.00 | 261.00 | 422.00 | | 150 | 35.00 | 64.80 | 101.00 | 150.00 | 277.00 | 447.00 | | 160 | | | 107.00 | 159.00 | 293.00 | 497.00 | | 180 | | | 119.00 | 177.00 | 325.00 | 547.00 | | 200 | | | 131.00 | 195.00 | 357.00 | 597.00 | Class4.8 Class5.8 Class6.8 Class8.8 Class10.9 Class12.9 | NO. | Mechanical or

physical property | Property class | | | 4.6 | 4.8 | 5.6 | 5.8 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9/12.9 | | | D≤16mma | d>16mmb | d≤16mm | | | Supplier | QBH | | | 1 | Tensile strength

Rm,Mpa | nom.c | 400 | 500 | 600 | 800 | 900 | 1000 | 1200 | | | max. | 400 | 420 | 500 | 520 | 600 | 800 | 830 | 900 | 1040 | 1220 | | | 2 | Lower yield strength

ReL,Mpa | nom.c | 240 | -- | 300 | -- | -- | -- | -- | -- | -- | -- | | | max. | 240 | -- | 300 | -- | -- | -- | -- | -- | -- | -- | | | 3 | Stress at 0,2 % nonproportional elongation

Rp0.2,Mpa | nom.c | -- | -- | -- | -- | -- | 640 | 640 | 720 | 900 | 1080 | | | max. | -- | -- | -- | -- | -- | 640 | 660 | 720 | 940 | 1100 | | | 4 | Stress at 0,0048 d non-proportional elongation for

full-size fasteners

Rpf,Mpa | nom.c | -- | 320 | -- | 400 | 480 | -- | -- | -- | -- | -- | | | max. | -- | 340e | -- | 420e | 480e | -- | -- | -- | -- | -- | | | 5 | Stress under proof load

Spf,Mpa | nom. | 225 | 310 | 280 | 380 | 440 | 580 | 600 | 650 | 830 | 970 | | Proof Sp,nom/ReL min Or

strength Sp,nom/Rp0.2min Or

rati Sp,nom/Rpf min | 0.94 | 0.91 | 0.93 | 0.9 | 0.92 | 0.91 | 0.91 | 0.9 | 0.88 | 0.88 | | | 6 | Percentage elongation

after fracture for

machined test pieces,A,% | min. | 22 | -- | 20 | -- | -- | 12 | 12 | 10 | 9 | 8 | | | 7 | Percentage reduction of area after

fracture for machined test pieces,Z,% | min. | -- | 52 | 48 | 48 | 44 | | | 8 | Elongation after fracture for full-size

fasteners,Af | min. | -- | 0.24 | -- | 0.22 | 0.2 | -- | -- | -- | -- | -- | | | 9 | Head soundness | No fracture | | | 10 | Vickers hardness, HV,

F≥98N | min. | 120 | 130 | 155 | 160 | 190 | 250 | 255 | 290 | 320 | 385 | | | max. | 220g | 250 | 320 | 335 | 360 | 380 | 435 | | | 11 | Brinell hardness, HBW

,F=30D² | min. | 114 | 124 | 147 | 152 | 181 | 238 | 242 | 276 | 304 | 366 | | | max. | 209g | 238 | 304 | 318 | 342 | 361 | 414 | | | Supplier | QBH | | | 12 | Rockwell hardness,HRB ,

HRB | min. | 67 | 71 | 79 | 82 | 89 | | | | max. | 95g | 99.5 | | | Rockwell hardness,

HRC | min. | -- | 22 | 23 | 28 | 32 | 39 | | | max. | -- | 32 | 34 | 37 | 39 | 44 | | | 13 | Surface hardness

HV 0.3 | max. | -- | h | h,j | h,j | | | 14 | Height of non-decarburized thread zone,E,mm | min. | -- | 1/2H1 | 2/3H1 | 3/4H1 | | Depth of complete decarburization in the

thread,G,mm | max. | -- | 0.015 | | | 15 | Reduction of hardness after retempering,HV | max. | -- | 20 | | | 16 | Breaking torque,

MB,N·m | min. | -- | in accordance with ISO 898-7 | | | 17 | Impact strength,

KVK,I,J | min. | -- | 27 | -- | 27 | 27 | 27 | 27 | m | | | 18 | Surface integrity in accordance with | ISO 6157-1n | ISO 6157-3 | | a Values do not apply for structural bolting.

b For structural bolting d W M12.

c Nominal values are specified only for the purpose of the designation system for property classes.See Clause 5.

d In cases where the lower yield strength ReL cannot be determined, it is permissible to measure the stress at 0,2 % non-proportional elongation Rp0,2.

e For the property classes 4.8, 5.8 and 6.8 the values for Rpf min are under investigation. The present values are given for calculation of the proof stress ratio only. They are not test values.

f Proof loads are specified in Tables 5 and 7.

g Hardness determined at the end of a fastener shall be 250 HV, 238 HB or 99,5 HRB maximum.

h Surface hardness shall not be more than 30 Vickers points above the measured core hardness of the fastener when determination of both surface hardness and core hardness are carried out with HV 0,3.

i Any increase in hardness at the surface which indicates that the surface hardness exceeds 390 HV is not acceptable.

j Any increase in hardness at the surface which indicates that the surface hardness exceeds 435 HV is not acceptable.

k Values are determined at a test temperature of −20 °C, see 9.14.

l Applies to d W 16 mm. m Value for KV is under investigation.

n Instead of ISO 6157-1, ISO 6157-3 may apply by agreement between the manufacturer and the purchaser. | | | | QBH 1008 | CHEMICAL COMPOSI % | | C | Si | Mn | P | S | Cr | Ni | Cu | Al | | 0.06 | 0.06 | 0.33 | 0.013 | 0.003 | 0.01 | 0 | 0.01 | 0.028 | QBH 1035 | CHEMICAL COMPOSI % | | C | Si | Mn | P | S | Cr | Ni | Cu | | 0.34 | 0.13 | 0.73 | 0.012 | 0.002 | 0.02 | 0.01 | 0.02 | QBH 10B21 | CHEMICAL COMPOSI % | | C | Si | Mn | P | S | Cr | B | | 0.2 | 0.04 | 0.81 | 0.017 | 0.007 | 0.017 | 0.0021 | QBH 1045 | CHEMICAL COMPOSI % | | C | Si | Mn | P | S | Cr | Ni | Cu | | 0.45 | 0.23 | 0.58 | 0.014 | 0.006 | 0.057 | 0.008 | 0.016 | QBH 40CR | CHEMICAL COMPOSI % | | C | Si | Mn | P | S | Cr | Ni | Cu | | 0.4 | 0.21 | 0.54 | 0.015 | 0.008 | 0.95 | 0.02 | 0.02 | QBH 35CRMO | CHEMICAL COMPOSI % | | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | | 0.35 | 0.22 | 0.59 | 0.01 | 0.003 | 0.93 | 0.01 | 0.01 | 0.21 | QBH 42CRMO | CHEMICAL COMPOSI % | | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | | 0.42 | 0.27 | 0.92 | 0.013 | 0.004 | 1.01 | 0.03 | 0.04 | 0.2 | |