1.5MPa PLC Spiral industrial Stainless Steel Pipe Coil For Cold Simmering

|

|

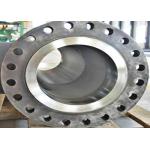

Spiral Coils For Cold Simmering In Boiler Plants Lined Pipe Fittings

Products Description: As the name suggests, the coil is a spiral pipe system. Such as disc-shaped aluminum-plastic pipes, such as floor heating pipe coils installed in the back shape, etc.

Quality Control: 1. The influence of lubrication on product quality during the bending process: In the traditional bending pipe production process, enterprises will adopt many methods to obtain better surface quality of the bend, including: adopting more advanced and high-grade bends Machine, use higher strength molds, or use lubricating products and other methods. 2. When the pipe is bent, the outside of the material is stretched, and the position of the neutral axis under pressure on the inside is different from the bending method. In the top-bending type (compression bending), the neutral axis is located about 1/3 away from the outer wall. When bending (returning) work, the neutral axis is located 2/3 away from the outer wall. Therefore, when thin-walled pipes are bent, it is beneficial to use the twist bending method. 3. The accuracy of the bent tire is also one of the factors affecting the quality of the bent tube. When we manufacture bent tires, in addition to the specification and size requirements to be controlled within a certain tolerance range, we also require users to select the corresponding bent tires according to the bent pipe diameter during use. Product Categories: 1. Aluminum-plastic composite pipe 2. Steel-plastic composite pipe 3. Aluminum alloy lined plastic composite pipe 4. Plastic coated steel pipe 5. Steel skeleton tube Performance: 1. Temperature and pressure resistance 2. Linear expansion coefficient 3. Linear expansion coefficient 4. Thermal conductivity 5. Water hammer resistance 6. Comprehensive cost Installation connection method: 1. Clamping installation 2. Hot melt installation 3. Electrofusion connection Care and maintenance: The process of boiler coil is to put an induction coil on the bending part of the steel

pipe, clamp the pipe head with a mechanical rotating arm, and pass

an intermediate frequency current into the induction coil to heat

the steel pipe. When the temperature of the steel pipe rises to a

plastic state, the steel pipe Use mechanical thrust to advance and

bend, and the bent steel pipe part is quickly cooled with coolant.

In this way, heating, advancing, bending, and cooling are performed

to continuously bend the bent pipe. As the name implies, the

galvanized elbow is galvanized on the basis of the elbow.

Company Profile:

Our Focus on the total needs of our client and our emphasis is on

the services and prompt solutions for all their critical purchasing

requirements We focus on the total needs of our clients from a particular industry,This reduces the need for most buyer to cope with multiple dealers for products of different size ,Variety ,Several different sources or products from various part of the world ,We also reduce the need for most buyers to deal with different salespeople and departments within the same trading company

Our Strength lies in Our People ,Our resources ,Our flexibility and our tireless commitment to serving our customers

|

| Product Tags: 1.5MPa Stainless Steel Pipe Coil Stainless Steel Pipe Coil PLC 1.5MPa industrial pipe fittings |

|

ASTM B338 Gr2 Titanium Alloy Cross Butt Weld Pipe Fitting |

|

Alloy 6000 Pressure Pipes Fittings in Wooden Cases |

|

Tee Alloy Pipe Fittings in Wooden Cases for B2B |

|

N04400 Nickel Alloy Pipe Fittings Polished Wooden Cases |

|

N08811 Alloy Steel ASME SB 366 Temperature Rating Up To 1200°F Packaging Bundles |

|

Factory high precision steel pipes fittings welding service pipe prefabrication |