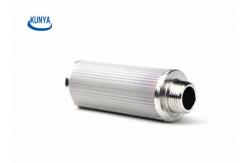

Customized Shipbuild Twill Weave Sintered Filter Elements

|

High Temperature Corrosion Resistant Micron-Level Multi-Layer Stainless Steel Sintered Mesh Filter Element For ShipbuildMulti-layer metal sintered mesh is a new type of filter material with a certain strength and overall rigidity, which is a new type of filter material with a certain strength and overall rigidity, which is laminated and sintered by a multi-layer metal wire woven mesh. The hole is easy to deform and unstable, and its comprehensive performance is higher than that of metal powder sintered, ceramic, metal fiber sintered filter felt and other products. Used in petroleum, energy, electric power, electronics and other fields.

1. Filtering form 1. Stainless Steel Sintered Mesh Filter Element Surface filtration: Relying on the filter material to capture the particles, the impurities are bridged on the surface to form a filter cake. This cake layer is the main filter medium. Due to the uniform pore size of this type of filter material, it can play a role of intensive reading control.

2.Stainless Steel Sintered Mesh Filter Element Deep filtering: The particles are captured in the deep layer of the filter material, not just on the surface. This kind of filter material is mostly composed of fibers, such as fiber sintered filter material and resin sintered filter material. Its accuracy is generally called the nominal accuracy. Two, filter classification cartridge filter materials are collectively referred to as filter cartridges, which can be divided into two categories: non-metallic and metallic. Among them, non-metals are divided into: fiber sintering, fiber winding and polypropylene folding. Metals are divided into: fiber sintering, powder sintering, wire mesh folding, and multilayer mesh sintering. The difference between deep filtration and surface filtration: The depth filtration type is mostly disposable, while the surface type can be cleaned and reused. The amount of trapped impurities of the deep type is usually much greater than that of the surface type, so the single use cycle is longer. Depth filtration and surface filtration have a large difference in pressure drop and flow rate. The surface filtration is closer to the *pair filtration, and the depth type is mostly the nominal accuracy. The surface type is generally not suitable for the filtration of soft and fiber impurities, while the depth type is suitable for the filtration of hard, soft and fiber impurities.

3. Stainless Steel Sintered Mesh Filter Element Product use: 1. Used as a dispersive cooling material in a warm environment; 2. Used for gas distribution, fluidized bed orifice material; 3. Used as high temperature filter material;

4. Used for high pressure backwash.

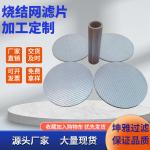

5. Stainless Steel Sintered Mesh Filter Element Main features: 1. It is not necessary to add internal support to make the filter element; 2. There is no material separation phenomenon; 3. Easy to backwash; 4. High corrosion resistance and not easy to damage; 5. Filtration degree: 2~60μm; 6. Operating temperature: -20~600℃; 7. Pressure difference: 3.2MPa; 8. Size: width 500mm, length 1000mm; 9. Number of layers: 2-6 layers. Stainless Steel Sintered Mesh Filter Element Features1) Sintering filter high strength: five layer screen sintering, high mechanical strength and compressive strength; 2) Sintering filter high precision: 2-200 um filtering particle size all can play uniformity of surface filtration performance; 3) Sintering filter heat resistance: but durable from - 200 degrees at most 650 degree continuous filtration; 4) Sintering filterclean sex: because the current good cleaning effect and surface filter structure, simple cleaning. Main application: 1) Sintering filter used in high temperature environment dispersion cooling materials; 2) Sintering filter used in gas distribution, liquid fluidized bed orifice plate materials; 3) Sintering filter used for high precision, high reliability and high temperature filtration materials; 4) Sintering filter used for high pressure reverse flushing oil filter.

Stainless Steel Sintered Mesh Filter Element Specifications

|

||||||||||||||||||||

| Product Tags: twill weave sintered filter elements shipbuild sintered filter elements twill weave sintered mesh filter element |

|

Race Car Filter Element 316L sintered felt folding filter tube |

|

steel sintered wire mesh 5 layers 100 75 50 40 micron 316 stainless steel sintered filter mesh |

|

Stainless Steel round hole perforated metal filter cylinders sintered wire mesh tube |

|

Tube Sintered Filter 1um 2 um 5um 10um 50um 100 150 Micron Stainless Steel Sintered Filter Cylinder |

|

Fluid plate in metal industry Sintered wire mesh in fluid bed of gas distribution Plasma welding sintered wire mesh |

|

Standard Size Stainless Steel Sintered Mesh Filter Screen(Multi layer),Sintered woven wire mesh |