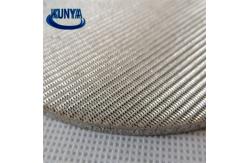

6 Layers 5 Micron Stainless Steel Sintered Mesh With Drainage Layer

|

6 Layers 5 Micron Stainless Steel Sintered Wire Mesh With Drainage LayerSintered Wire Mesh Introductions

Sintered wire mesh is the combination of different layer of wire mesh sintered under high temperature inert gas inside the furnace. During the sintering (diffusion bonding) process, indiviual wires and each adjacent layer of the mesh bond to each other.After cooling, the sintered wire mesh is rigid and completely flat readily to be finished. Sintered wire mesh combines the property of the different layers

and obtains more superior characteristics, such as: - Maintaining steady filter rating even under high working pressure and temperature; - Notably durable with robust construction; - Excellent cleanability and dirt holding capacity; - Ability to be processed by pleating, cuting, welding, punching, bending etc; - Versatile configuration for various application due to layer material and quantity choice. Tyipical 5 layer sintered wire mesh configuration: Sintered Wire Mesh Specifications

Sintered Wire Mesh Advantages * High strength and durability since high temperature sintering; * Anti-corrosion, and heat resistance up to 480℃; * Steady filter rating from the 1micron to 100 micron; * Filter mesh not easy to deform because of two protective layers; * Can used for uniform filtration in high pressure or high viscosity environment; * Suits for cutting, bending, punching, stretching, and welding.

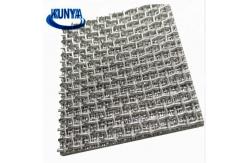

Sintered Wire Mesh Types

Main products we provided, 5-Layer / 7-Layer Sintered Wire Mesh,

Dutch Woven Sintered Wire Mesh, Perforated Metal Sintered Wire

Mesh, Plain Sintered Square Woven Wire Mesh, Sintered Filter

Elements, Sintered Mesh Filter Cartridges, Sintered Wire Mesh

Filter Disc, Sintered Wire Mesh Laminates, Sintered Wire Mesh

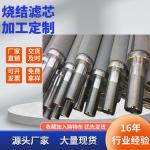

filter tube. Sintered Wire Mesh Applications Widely used in polymer filtration, petrochemical, electronic high temperature gas dust removal, oil filtration in the refining process, viscose filtration, pre filtration of ultrafiltration device, vacuum pump protection filter, membrane support, catalyst carrier, automobile airbag, fuel filter of aircraft ship , hydraulic filter system Sintered Wire Mesh Filter Features *High dirt holding capacity, high filtering accuracy, slow pressure rising, long replacement cycle *High porosity and excellent permeability which results in low pressure drop and large flow *High temperature resistance, corrosion resistance of acid, alkali, and organic solvent proof *Reinforcing type, thickening type, add-protection mesh type and other types are available |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: 5 micron stainless steel sintered mesh 6 layers stainless steel sintered mesh sintered mesh with drainage layer | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Dutch Weave Sintered Wire Mesh Perforated Metal Sintered Wire Mesh |

|

Sintered Square Plain Woven Wire Mesh |

|

Standard 5-layer sintered wire mesh 1um-250um |

|

Custom Stainless Steel Sintered Mesh For Water Treatment |

|

1.7mm Hastelloy Alloy Sintered Wire Mesh 1 Micron |

|

304 316l Sintered Stainless Steel Filter Disc Air Liquid Solid Filtration Use |