Programmable New Corrosion Testing Machine Salt Spray Chamber

|

|

Programmable New Corrosion Testing Machine Salt Spray Chamber

Product Description

Equipment Summary Salt spray testing machine used to test the corrosive resistance of products whose the surface was treated with paint, electroplating, inorganic and organic film, anode handling, anti-rust oil,etc.

Corresponding Standard 1. GB/T 2423.17-1993 salt spray test 2. GB/T 2423.18-2000 salt spray test 3. GB/T 10125-1997 salt spray test 4. ASTM.B117-97 salt spray test 5. JIS H8502 salt spray test 6. IEC68-2-11 salt spray test 7. IEC68-2-52 1996 salt spray test 8. GB.10587-89 salt spray test 9. CNS.4158 salt spray test 10. CNS.4159 CASS Accelerated acetic acid copper salt spray test 11. GB/T 12967.3-91 CASS Accelerated acetic acid copper salt spray test 12. ASTM B117 Standard Practice for Operating Salt Spray (Fog) Apparatus

Technical Parameters

Detailed Configurations As Follows 1. Machine Material (A) testing room using PVC polyvinyl chloride plate (from Taiwan), acid-resisting and alkali-resisting, cleaning easier. (B) cover of testing room using acrylic panels (imported organic glass), the thickness is 5mm. (C) reagents added bottles attached with water gauge, cleaning easy and not easy to break. (D) saturated air barrels is made of SUS # 304 stainless steel. (E) testing room to adopt indexing frame, can be arbitrarily adjust the angle, Surrounded by fog and placed more piece .

2. According to CNS JIS ASTM GB2423.19 specifications, can be set constant temperature to control (A) Salt spray test: NSS, ACSS 1. testing room : 35 ℃ ± 1 ℃ 2 saturated air barrels : 47 ℃ ± 1 ℃ (B) anti-corrosion test: CASS (copper acetate) 1.testing room: 50 ℃ ± 1 ℃ 2 saturated air barrels: 63 ℃ ± 1 ℃

3. Air Supply System: Air pressure 1Kg/cm2 Two-stage adjustments (coarse / fine-tuning). (A) the first paragraph for the rough adjustment 2-2.5Kg/cm2, the second paragraph to fine-tune 1Kg/cm2. (B) Testing configuration is switch connector designed for SO2.

4. Spray Form (A) Using Bo Nute principle to draw brine and then saline spray, atomization uniform, non-blocking and crystallization, so that ensure continuous spraying. (B) Nozzle: The nozzle is made of special glass, adjust spray volume and spray angle. (C) spray volume: Adjustable 1 ~ 2ml (80cm2/hr) (average of 16-hour volume).

5. Heating Devices By direct heating, warming up faster and reduction of standby time, when the temperature arrives automatically switch ON / OFF, make temperature accuracy, low power consumption (heating tube is made of titanium alloy).

6. The Control System

7. Add Water Systems Using automatic water replenishment system, automatic replenishment when the water level is too low.

8. Safe Protective Device (A) low water level, automatically cut off power supply. (B) over-temperature, automatic cut off the power supply. (C) attached to the safe warning light device.

9.Accessories PH test paper 1 pcs

Detailed image

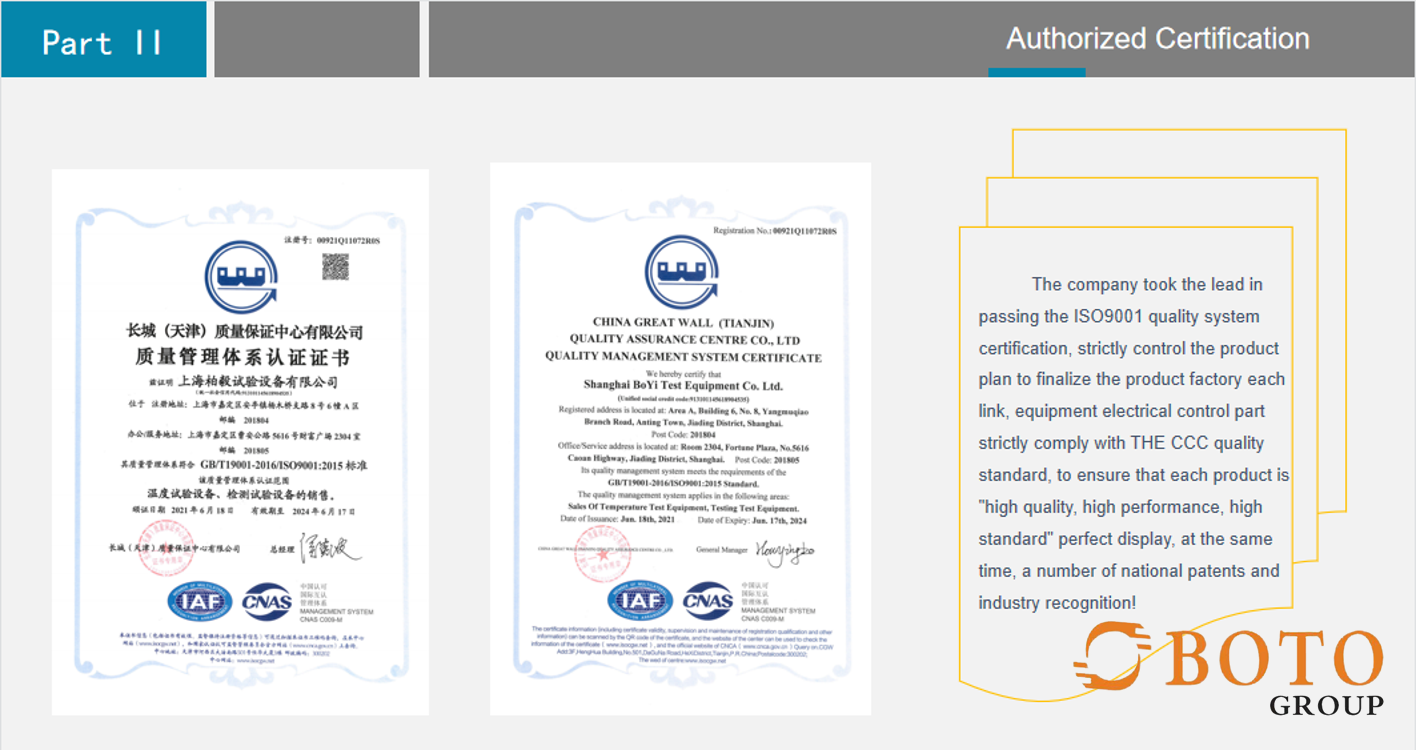

Company introduction

|

||||||||||||||||||||||

| Product Tags: Programmable Salt Spray Chamber 480L Corrosion Testing Machine ACSS Acetic Acid Corrosion Testing Machine |

|

Corrosion Test Cabinet Customized Chamber Size 0.2Mpa-0.4Mpa Spray Pressure For Accurate Corrosion Measurement |

|

R404A / R23 Thermal Shock Test Chamber, -40C~150C Two Zone, 10s Conversion Time |

|

High And Low Alternating Test Box Quick Change Chamber Temperature Shock Tester Thermal Shock Test Chamber |

|

220V Precision Humidity Temperature Sensor Damp Heat Test Chamber For Varied Testing Environments |

|

Xenon Lamp Aging Chamber Lab Instrument Xenon Arc Test Chamber climatic chamber |

|

Salt Water Spray Test Chamber PLC Control Salt Spray Test |