Wet Concrete Dosing System-Color Dosing System

|

Product Description:An auto wet concrete dosing system, also known as an automatic concrete batching plant or automatic concrete mixing plant, is a system used in construction to automatically measure, mix, and dispense the required ingredients for producing wet concrete. It is designed to streamline the concrete production process and improve efficiency. Here's a general overview of how an auto wet concrete dosing system works: 1,Ingredient Measurement: The system typically consists of multiple storage containers or silos that hold various raw materials such as cement, aggregates (such as sand and gravel), water, and sometimes admixtures (chemical additives). Each ingredient has its dedicated storage container.

2,Batching Control: The system is equipped with sensors, weighing devices, and a control unit. The control unit monitors and controls the entire batching process. It ensures accurate measurement and precise control of the ingredient proportions according to the desired concrete mix design.

3,Material Transfer: When a concrete batch is initiated, the system activates the necessary mechanisms to transfer the required amounts of each ingredient from their respective storage containers to a central mixing unit. This may involve conveyor belts, screw conveyors, or pneumatic systems, depending on the design of the batching plant.

4,Mixing Process: Once all the ingredients are transferred to the central mixing unit, they are thoroughly mixed to achieve a homogeneous concrete mixture. The mixing unit can be a twin-shaft mixer, a planetary mixer, or a drum mixer, depending on the specific plant configuration.

5,Discharge: After the mixing process is complete, the system automatically discharges the freshly mixed concrete into a transit mixer truck or directly into a concrete pumping system for transportation to the construction site. The discharge can be controlled by gates, chutes, or other mechanisms.

6,Repeat Batching Cycle: The auto wet concrete dosing system is capable of continuously batching new batches of concrete as needed. It can be programmed to produce different mix designs and adjust the batch sizes based on the construction requirements. Features:

Technical Parameters:

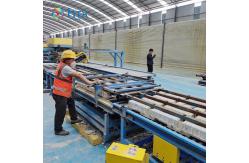

Applications:HTX Concrete Dosing Machine: High Efficiency and Low Cost Automatic

Concrete Casting Wet Doser HTX concrete dosing machine is a perfect choice for paver block manufacturing and artificial stone production lines. It is designed to be highly efficient and low cost, making it an ideal choice for industrial production. With a capacity of 1000-1200m2, it is an indispensable part of any serious production line. The HTX-P-01 model concrete dosing machine is manufactured by HTX in Henan. It is an automatic concrete casting wet doser machine with a number of features that make it stand out from the competition. It is designed to be highly efficient, making it a perfect choice for industrial production. It also features a voltage that can be customized to meet the needs of the customer. The HTX concrete dosing machine is designed with the highest quality standards in mind. It is built to last and to provide the highest levels of accuracy and performance. It is also designed to be easy to use and maintain, making it a perfect choice for any industrial production line. The HTX concrete dosing machine is the perfect choice for any industrial production line that needs a highly efficient and low cost machine. With its high efficiency and low cost, it is the perfect choice for any serious production line. It is also designed to be easy to use and maintain, making it a perfect choice for any serious production line. Customization:HTX-P-01 Automatic Concrete Casting Wet Doser Machine

Support and Services:Concrete Dosing Machine Technical Support and Services

|

||||||||||||||||||||||

| Product Tags: Wet Concrete Dosing System Color Concrete Dosing System |

|

Concrete Sleeper Walls Machine Artificial Stone Manufacturing Machine |

|

Easy To Operate Concrete Dosing Machine For Artificial Stone Manufacturing With 1000-1200m2 Capacity |

|

Stacked Stone Concrete Sleepers Machine Artificial Stone Production Line Wet Cast Machinery |

|

Concrete Sleeper Walls Machine Artificial Stone Manufacturing Machine |

|

Efficient Concrete Dosing Machine Rubber Mould Paver Block Making Machine |

|

Interlocking Paver Block Making Machine Artificial Stone Manufacturing Machine |