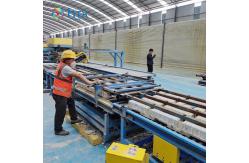

Full-Automatic Sandstone Retaining Wall Making Machine Artificial Stone Manufacturing Machine

|

|

Sandstone retaining wall making machines are specialized machinery and equipment used to manufacture sandstone blocks or components for constructing retaining walls. Sandstone retaining walls are commonly used in landscaping and construction projects to create sturdy and visually appealing structures that retain soil and prevent erosion. The machines automate the process of producing sandstone blocks or components, ensuring efficiency, accuracy, and consistency in the manufacturing process.

Specification:

Applications

Support and Services

Wet Cast Machinery technical support and services include:

|

|||||||||||||||||||||

| Product Tags: automated fence panel machine fence panel making machine panel master fencing machine |

|

High Efficiency Sandstone Retaining Wall Making Machine Veneer Stone Production Line |

|

|

Garden Wall Cladding Artificial Stone Mold Silicone Injection |

|

Stacked Stone Concrete Sleepers Making Machine Retaining Block Making Machine |

|

1200-1500m2/Day Cultured Stone Making Machine Wet Cast Machinery |

|

Auto Wet Conrete Dosing System Artificial Stone Panel Making Feeding Machine |

|

Feeder Concrete Dosing System Wall Fence Panel Production Line |