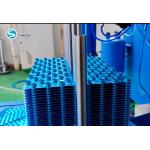

Product Description:

The Variable frequency constant of the Radiator Fin Forming Machine

is 25~120 Strokes Per Minute. This means that you can easily adjust

the speed of the machine to meet your specific needs. The machine

is capable of producing fins with a maximum width of 300mm, making

it perfect for larger projects.

The Radiator Fin Forming Machine is a heavy-duty machine that is

built to last. It has a total weight of 1500KG, which makes it a

sturdy and reliable machine that can handle even the toughest jobs.

The machine operates at a pressure of 0..8Mpa and is designed to

work with 1.5mm-2mm tube thickness aluminum.

The Radiator Fin Forming Machine is a versatile machine that can

produce a wide range of fins. It is designed to work with Aluminium

6.5-10 Tube Pitch Radiator Fin Machine and can also be customized

to meet your specific needs. The machine comes equipped with Flat

Fin Machine Multi Hobs, which ensures that you get consistent and

high-quality results every time.

The Radiator Fin Forming Machine is an ideal machine for anyone who

needs to produce high-quality fins quickly and efficiently. Whether

you're in the HVAC industry or you need to produce fins for other

applications, this machine is the perfect solution. With its

variable frequency constant, maximum fin width of 300mm, and

heavy-duty construction, the Radiator Fin Forming Machine is a

reliable and powerful machine that will help you get the job done

right.

Features:

- Product Name: Radiator Fin Forming Machine

- Machine input KW: Variable Frequency Stepless Speed Regulation

- Flatness during rise of die table: ≤0.03mm

- Power supply: Three Phase 380V±10% 50Hz±2%

- Variable frequency constant: 25~120 Strokes Per

- Highest flatness of lower die table: ≤0.02mm

- High Speed Radiator Fin Forming Machine 5mm Height 1.5mm Tube

Thickness

- AC220V 1.5 Tons Automatic Fin Forming Machine Single Blade

- Aluminium 6.5-10 Tube Pitch Radiator Fin Machine

- Fin Tube Machine Customized

Technical Parameters:

| Fin (tooth height x tooth spacing) | 12×20mm |

| Machine weight | 1500KG |

| Machine input KW | Variable Frequency Stepless Speed Regulation |

| Maximum fin width | 300mm |

| Power supply | Three Phase 380V±10% 50Hz±2% |

| Flatness during rise of die table | ≤0.03mm |

| Highest flatness of lower die table | ≤0.02mm |

| Variable frequency constant | 25~120 Strokes Per |

Applications:

- Manufacturing Plants: The Radiator Fin Forming Machine is ideal for use in manufacturing

plants that produce radiators for a wide range of applications.

This machine is capable of producing fins with a tooth height x

tooth spacing of 12×20mm, making it perfect for use in the

production of aluminium 6.5-10 tube pitch radiator fins.

- Customized Fin Tube Machine: The Radiator Fin Forming Machine is customizable to suit the

specific needs of customers. The machine can be tailored to produce

fins of different widths, lengths, and heights, making it perfect

for use in the production of customized fin tube machines.

- Automatic Fin Forming Machine: The AC220V 1.5 Tons Automatic Fin Forming Machine Single Blade is

an excellent example of the Radiator Fin Forming Machine. This

machine is capable of producing high-quality fins without the need

for manual intervention, making it perfect for use in high-volume

manufacturing plants.

- High-Speed Radiator Fin Forming Machine: The High Speed Radiator Fin Forming Machine 5mm Height 1.5mm Tube

Thickness is capable of producing fins at a rate of 25~120 strokes

per minute, making it perfect for use in high-speed manufacturing

plants. This machine is also capable of producing fins with a

maximum width of 300mm, making it ideal for use in a wide range of

applications.

Overall, the Radiator Fin Forming Machine is a versatile piece of

equipment that can be used in a wide range of occasions and

scenarios. Whether you are producing radiators for the automotive

or industrial industry, or need a customized fin tube machine, the

Radiator Fin Forming Machine is an excellent choice.

Packing and Shipping:

Product Packaging:

The Radiator Fin Forming Machine will be packaged in a sturdy

wooden crate to ensure safe and secure transportation. The crate

will be sealed and marked with the product details and shipping

information.

Shipping:

Shipping will be arranged by our team and will be delivered to the

address provided by the customer. Shipping fees will be calculated

based on the destination and weight of the product. Customers will

be provided with a tracking number and regular updates on the

status of their shipment.