High-Performance Aluminum Brazing Furnace With 316L Stainless Steel

Braided Mesh Belt

Product Description:

Our four sections aluminum brazing furnace is specially designed to

meet the needs of various brazing processes for aluminum products.

It can reach a maximum temperature of 650-700 degree and adopts

spray drying air cooling area, continuous tunnel type natural gas

brazing oven and radiantor tube heating. The nitrogen purity is

above 99.9995%, and the nitrogen consumption is about 35~45m³/h.

The cooling method is air cooling and the power supply is AC380V.

The temperature accuracy is ±3℃. Moreover, the three-phase 50HZ

AC380V power supply ensures the high-quality performance of the

furnace.

Technical Parameters:

| Parameter | Value |

|---|

| Maximum height of workpiece | 250mm |

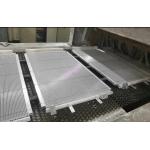

| Material of Mesh belt | 316L Stainless Steel Braided |

| Temperature Accuracy | ±3℃ |

| Mesh belt transmission speed | 200—1500mm/min (Continuously Adjustable ) |

| Heating up time | 0.5-1h |

| Cooling Method | Air Cooling |

| Rated power of Drying zone | 103.45KW |

| Heating Temperature | 600-650℃ |

| Control System | PLC Control |

| Nitrogen consumption | About 35~45m 3/h |

Applications:

The Sunhope Aluminum Brazing Furnace is designed to meet the needs

of customers who require a reliable and efficient furnace for

aluminum radiator brazing. It features a maximum height of 250mm

and a brazing section with plug-in heating elements that can be

heated up within 0.5-1 hour. The size can be customized according

to the users’ requirements. The mesh belt transmission speed, from

200 to 1500mm/min, is continuously adjustable. The face height of

mesh belt reaches 900mm. Furthermore, it has a nitrogen consumption

of 35-45 m3/h and a spray drying air cooling area with a 650-700

degree temperature. The continuous tunnel type natural gas brazing

oven is also equipped with this furnace to ensure maximum

performance.

Customization:

Sunhope Continuous Tunnel Type Natural Gas Brazing Oven is designed

to provide precise temperature control and protection for aluminum

brazing. It features with 4 sections, including heating temperature

of 600-650℃, rated power of 103.45KW, temperature accuracy of ±3℃

and Nitrogen consumption of about 35~45m 3/h. The aluminum brazing

furnace also has Spray Drying Air Cooling Area and Nitrogen

protection for superior performance. The size of the oven is

customizable to meet different needs.

Support and Services:

Aluminum Brazing Furnace Technical Support and Service

We provide technical support and service for our Aluminum Brazing

Furnace. Our team of certified engineers are available to assist

with any technical issues you may encounter with our products.

We offer on-site service and repair for our Aluminum Brazing

Furnace. We provide a thorough inspection and testing of the

furnace before and after service, to ensure all components are

working properly.

We also provide remote technical support for our Aluminum Brazing

Furnace. Our experienced technicians are available to answer any

questions you may have and provide assistance. We also have an

online knowledge base with helpful articles and tutorials.

If you require any additional technical support or service for your

Aluminum Brazing Furnace, please don't hesitate to contact us.

Packing and Shipping:

Packaging and Shipping of Aluminum Brazing Furnace:

- The aluminum brazing furnace is carefully packaged in a wooden box

for protection during shipping.

- The box is then secured with shrink wrap and placed in a corrugated

cardboard box.

- The box is then shipped with a reputable carrier to ensure its safe

arrival.