Temperature Accuracy ±3℃ Aluminum Brazing Furnace with Stainless

Steel and PLC Control

Product Description:

Aluminium Brazing Furnace is designed to provide efficient and

reliable heat treatment for brazing of aluminium components.

Equipped with an advanced radiant tube heating system, the furnace

is capable of quickly heating up to 250mm in height with cooling

air. It is suitable for continuous tunnel type brazing ovens and

can be used in both natural gas and nitrogen-enriched atmospheres.

The heating time is around 2-3 minutes, and the face height of the

mesh belt is up to 900mm. The furnace is powered by a three-phase

50HZ electric motor and consumes low levels of nitrogen. It is

durable, economical and safe to use for all kinds of aluminium

brazing applications.

Features:

- Product Name: Aluminum Brazing Furnace

- Mesh belt transmission speed: 200—1500mm/min (Continuously

Adjustable )

- Cooling Method: Air Cooling

- Power Supply: AC380V

- Heating Time: 2-3min

- Material: Stainless Steel

- Radiantor Tube Heating

- Nitrogen Consumption

- Three Phase 50HZ

- Four Sections Aluminum Brazing Furnace

- 650-700 Degree Spray Drying

- Air Cooling Area

- Continuous tunnel type Natural gas brazing oven

Applications:

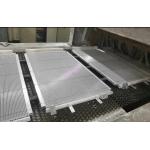

The Sunhope four-section aluminium brazing furnace is the perfect solution for

industrial brazing. With its high-temperature radiant tube heating,

nitrogen consumption rate of 35-45m3/h and three-phase 50HZ power supply, this brazing furnace can

reach temperatures of up to 650-700°C. The stainless steel material

ensures long-term durability and the rated power of the drying zone

is 103.45KW. It also comes with an air-cooling area for a more

efficient cooling process. The size of the furnace can be

customized to meet the needs of the customer.

The Sunhope four-section aluminium brazing furnace is perfect for a

variety of applications including brazing, welding, heat treating,

hardening and tempering. It is ideal for the brazing of aluminium,

copper and other metals, offering superior brazing results with

minimal heat loss. The furnace is also suitable for a range of

industrial use, from manufacturing to construction.

The Sunhope four-section aluminium brazing furnace is the perfect

choice for high-efficiency brazing processes. With its

high-temperature radiant tube heating, nitrogen consumption rate of

35-45m3/h and three-phase 50HZ power supply, this brazing furnace can

easily meet the demands of any industrial brazing operation.

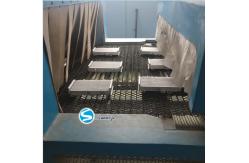

Technical Parameters:

| Parameter | Value |

|---|

| Nitrogen consumption | About 35~45m 3/h |

| Cooling Method | Air Cooling |

| Maximum height of workpiece | 250mm |

| Face height of mesh belt | 900mm |

| Heating Temperature | 600-650℃ |

| Heating up time | 0.5-1h |

| Size | Customized |

| Rated power of Drying zone | 103.45KW |

| Power Supply | AC380V |

| Heating Time | 2-3min |

| Type | Continuous tunnel type Natural gas brazing oven |

Customization:

Sunhope Aluminum Brazing Furnace- Brand Name: Sunhope

- Place of Origin: Guangdong, China

- Cooling Method: Air Cooling

- Mesh belt transmission speed: 200—1500mm/min (Continuously Adjustable )

- Heating Method: Radiant Tube Heating

- Heating up time: 0.5-1h

- Temperature Accuracy: ±3℃

- Continuous tunnel type Natural gas brazing oven

- 250mm Maximum Height Aluminum Radiator Brazing Furnace 35~45m 3/H

Nitrogen Consumption

Support and Services:

Aluminum Brazing Furnace Technical Support and Service

At XYZ, we are committed to providing the highest level of

technical support and service to our customers. Our team of

experienced engineers and technicians are available to assist you

in selecting the right Aluminum Brazing Furnace for your needs. We

offer:

- In-depth consultation to determine the best Aluminum Brazing

Furnace for your application

- Installation and commissioning of the furnace

- Expert troubleshooting and maintenance services

- Training and technical support to ensure optimal efficiency

- Parts and accessories for all of our Aluminum Brazing Furnaces

For more information about our Aluminum Brazing Furnace technical

support and service, please contact us today.