CNB Continuous Aluminum Brazing Furnace Quality Furnace Brazing Equipment Industrial Furnace

Brazing Aluminum

Product introduction:

Brazing:

For aluminum brazing in nitrogen furnace: a flux spraying device sprays flux onto

the workpiece, and heats the workpiece to 150 ℃ ~ 250 ℃ for drying

through the drying furnace. When the temperature in the brazing

furnace with protective atmosphere reaches 610 ℃, the workpiece is

brazed. After cooling by water cooling and air cooling, the

workpiece is unloaded from the unloading table. The process is as

follows:

Welding parts → flux spraying → conveying device → drying furnace →

conveying device → heating furnace → brazing furnace → water

cooling chamber → air cooling chamber → conveying device.

(1) Flux spraying A conveyor chain carries the workpiece through a closed flux

chamber, in which water containing flux is sprayed on the

workpiece. After spraying, the excess flux on the workpiece is

removed by an air knife, and then the workpiece is transported to

the drying oven.(2) Drying processAfter spraying the flux, the parts need to be dried in the drying

oven, and the temperature is usually about 200 ℃. Care should be

taken to prevent the heat exchanger from overheating, which may

lead to the formation of high-temperature oxides on the aluminum

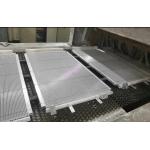

surface.(3) Continuous brazing furnace The brazing furnace must ensure that the temperature of the workpiece is

increased above 20 ℃ every minute, so that the surface coating

solder reaches the melting point (591 ℃). The temperature balance

of the workpiece is ± 3 ℃, and the protective atmosphere of

nitrogen is maintained in the furnace. The control of workpiece

temperature and the consistency of each workpiece temperature are

very high, so the heating chamber is divided into several control

areas. The more areas, the better the temperature distribution

control of the workpiece. Any large fluctuation will lead to

insufficient or excessive brazing of the workpiece.Product quick details: | Mesh belt operating surface height | 900mm | | Normal operating temperature | 600~650℃ | | Furnace temperature uniformity | ±3℃ | | maximum service temperature | 700℃ | | effective working size | 1000mm(Mesh belt width)×250mm(Height of mesh belt) | | The channel size | 1050mm×300mm(Straight edge height) | | Temperature control zone | 6 points in Section 6 of Section 3 (temperature measurement) | | Temperature measuring point layout | The upper and lower of each section + furnace temperature

measurement | | design power | 240KW±10% | | Temperature control mode | PID,The work pressure regulating | | heating mode | resistance wire | | length of heating zone | 6M | | conveying chain | SUS316L,Wire Φ 3 mm, wear silk Φ 3.5 mm |

Company introductions:

Our company has been engaged in the

manufacture and development of automobile radiator condenser

products for more than 15 years. Most of the products are sold to

all countries and regions in the world, and have accumulated rich

production experience.Our company is good at manufacturing all the

process of the radiator tank production line.In recent years,many

companies from other countries in the same industry also bought the

CKD from us and purchased the machine equipment from us as well.

With the development of heat exchange

industry, more and more countries and regions are committed to

building local radiator condenser plants. With our understanding of

the industry, we have been helping foreign customers to set up

radiator factories and provide the production machine in the region

in the past five years. We provide customers with pre-sale and

after-sale equipment design and service according to the size of

our products.In the meantime we will also provide the material to

our customers as well. We will send technicians to guide the

installation on site to ensure the smooth production of the

customer's factory, and provide free consultation service in case

of any doubt in the production process.

At the same time, our company provides

customers with all kinds of radiator, condenser required hardware

and plastic components. Ensure the supply and quality of finished

products.

If you are interested in setting up a radiator

factory in your place or buying any products , please contact us

and we will provide you with the best service and best price.

FAQ:

1.Does the aluminum Brazing furnace machine use gas?

The aluminum Brazing furnace machine can use natural gas as a

productive energy source.

2.How to know what kinds of specifications of the aluminium brazing

furnace machine should be customized?

The customers provide the productions plan ,the biggest size of the

core and the dimensions of the production workshop.The engineer

will give the best cost-effective solution according to the

information provided.

3.What’s the style of spray of the aluminum Brazing furnace

machine?

The spray of the aluminum Brazing furnace machine can be divided

into dry electrostatic powder spray style and aqueous solution

spray style.

4.Does the aluminum Brazing furnace machine is customized or

standard size?

The aluminum Brazing furnace machine is customized by customers

according to their respective capacity requirements and product

series specifications. |