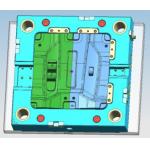

Project Risk Assessment Injection Mold Tooling Die

|

|

Project Risk Assessment Big Plastic Part Precision Plastic Tool Die/ODM/OEM Custom Sign according to your design drawing or Samples.

We have High-Speed CNC machines as well as Precision EDM machines,wire cutting machines and Milling machines as well as Drilling and Grinding machines .In house mold shop provide you precise molds

Our advatage as following:

Pretty competitive price,we offer good services and excellent

communications. Delivery time is very on time,can catch your delivery time as your requirements well.

Company Profile

Founded in 2010,we are OEM specialized in mold design & manufacture, injection molding and products assembling for more than 10 years with much experience. The product rangs include automotive, electronic,electrical appliance,medical treatment, communications and other other fields. We have one group of outstanding mold engineers and advanced mold processing/manufacture equipment. We are high technology enterprises with certification ISO9001

qualtiy system. Our mould and parts are mostly exported to

European,America,and other many countries for highly positive and

mutual trust.

Outdoor Scene

Mould Workshop

Injection Molding Workshop(20 injection machines)

Dustless Injection Workshop (3 injection machines) Engineering Department Packing & Delivery Packing Details : carton for mass production,wooden box for mould. Delivery Details : 15-25 days when receiving money.

1. Special logistics packaging

2. Suitable carton size

3. Shock bubble film FAQ Q: Are you trading company or manufacturer ? A: We are factory.

Q: Do you have the checking system to make sure the mould quality? A: We have a complete management system. Our project dept. will arrange mould checking and supply the checking report in detail. Only when the mould is qualified, can the mould be shipped out.

Q: What are our Engineering capabilities included? 1. Parts design. 2. R&D products. 3. Prototype design and production assembly. 4. Reputable design software used for all design work. 5. Mould design. 6. Mould Manufacture.

Q:What is beneficial for you? 1. Free quotation for your comparison. 2. Design mould with price priority, easily processing and quality assurance. 3. Get a strategic long-term partner. 4. Get the best service.

Q: What should be provided to get price? Samples , pictures with dimension , drawings and specific requirements.

Q:Can you make the mold and also supply us the injection molding plastic product? A:Yes, we can make the mold and also help you to molding the plastic product for you.

Q:Can you make insert mold? Yes, we can do this type mold, usual the insert material is metal insert, or hard plastic part, we have also experience to make 3color or material mold, we usual call this over mold.

Q:Can you make multi-cavity mold? Yes, we can, we can build some molds with 16, 32 ,48cavities even more.

Q:Can you help us to improve the structure design? Some customer have no experience on the mold technology, so the production usual need to improve the sturture to help save mold cost or improve the surface quality, yes we can help you on this.

Q: Can you help us to make the prototype and mold and molding product and painting or printing? Yes, we can help the client from the prototype to the final product, we call this one-stop servise.

|

||||||||||||||||||||||||||||

| Product Tags: LKM injection mold tooling injection mold tooling Die |

|

Multi Cavity Precision Plastic Injection Moulding For Auto Parts |

|

Polishing Painting Precision Plastic Mould For Household Appliances |

|

OEM Custom Plastic Injection Mold Tooling Automotive Parts Industrial Parts |

|

Custom Injection Molded Shell High Precision Tooling Die Making Service |

|

Customized High Precision Plastic Mould Products Maker Injection Mold Mouldings |

|

High Precision Multi Component Injection Moulding |