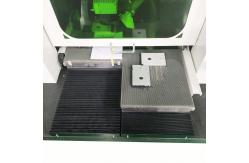

Eta Aluminum Manual Tubelight PCB Separator , Cutting Laser Depaneling Machine

|

|

PCB Separator Laser Depaneling Cutting Machine Eta Aluminum Manual Tubelight

What is PCB Depaneling?PCB (printed circuit board) depaneling, also called singulation, is the process of removing numerous smaller, individual PCBs from a larger multi-PCB panel produced during manufacturing. The depaneling process was created in order to increase throughput of PCB manufacturing lines as circuit board sizes reduced. At CMS Laser, our depaneling process has the advantage of speed, pin-point accuracy, no tooling cost or wear, no part induced stress, and no cutting oils or other waste. Demand Driven by SizeAs technology continues to evolve, the gadgets we use become more advanced and often decrease in size. This reduced size requires smaller PCBs. With no set standard for PCBs, every board is designed for a specific item. Therefore, the process for depaneling separate boards from a multi-image board is unique. Production factors such as stress, precision and cleanliness are paramount to keeping board defects to a minimum.Depaneling MethodsPCBs are typically manufactured in large panels containing multiple boards at a time, but can also be produced as single units if need be. The depaneling of PCBs process can be fully automatic, manual, or semi-automatic. There are several methods used, including laser PCB depaneling, within the electronics industry. Let’s examine what they are: Punching/Die Cutting:The punching method is the process of singular PCBs being punched out of the panel through the use of a special fixture. The punching fixture has sharp blades on one part and supports on the other. A different die is required for each board and dies must frequently be replaced to maintain sharpness. Although the production rate is high, the custom-designed fixtures and blades require a reoccurring cost.

Feature:

1.High Speed Steel Linear Blades PCB Depaneler PCB Depaneler With High Components

2. The shaft of the knives( top and bottom) is design to be an an integral whole, it is convenient to install, pick and place.

3.This machine adopts computer screen control with a counting device which can be preset production. Gap of the cutting tool displayed by the display screen directly.

4.All the v-cut pcb board can be cut by this machine.

5. Using the machine to cut, reduce stress, prevent the solder joint cracking.

6. Pcb board is cut by multiple cutters which can cut several board once.

7. The machine top cutter wheel can be slightly adjust:0-5mm.

8. The distance between the knives can be adjusted, and it is suitable to cut single pcb board within width 15-20mm.

9. Blade is made of SKH51 high speed steel with long service life and wear resistance.

10 Cutting speed can be set and conveniently adjusted by turn-knob.

11.Install conveyer belt, pcb board which is cut can be sent out directly, then docking with the next machine and reducing the times of artificial pick and place. This machine can cut LED panel, fiberboard, aluminum board (more than 400mm ) and special board.

12. With several knives, the machine operates simply and efficiently and is suitable for mass production.

Specification:

|

||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Aluminum PCB Separator Tubelight Laser Depaneling Machine |

|

15KW Single Phase Induction Heating Machine Metal Smelting Welding Equipment 250V |

|

High Frequency Solid State Welding Machine For Straight Seam Pipe Tube |

|

Hightest Frequency Safety And Efficiency Heating Equipment Low Power Consumption |

|

25 KW Automatic Industrial Machine 340V-430V HF Fully Functional And Has High Performance |

|

Handheld Polisher Grinding Machines Concrete Terrazzo Floor Polishing Machine 4.5kw |

|

Concrete Floor Grinding Polishing Machine Marble Epoxy Diamonds Electric Planetary Propane |