Product Description:

< 0.8 Um. This ensures a smooth and uniform surface for the

deposition of thin films and coatings. Additionally, our targets

have a Purity level of 99.99%, ensuring that the deposited films

and coatings have a high level of purity and quality. Our Metal

Sputtering Targets are available in a range of thicknesses, from 10

to 600mm. This makes them suitable for a wide range of

applications, from small-scale R&D to large-scale industrial

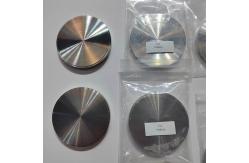

production. To ensure that our Metal Sputtering Targets reach our

customers in the best possible condition, we use advanced packaging

techniques. Each target is carefully packed and sealed to prevent

any damage or contamination during shipping. Our Metal Sputtering

Targets are compatible with various deposition techniques,

including DC and RF sputtering. They are also suitable for use with

various equipment, such as an Electrostatic Powder Coating Gun or a

Conveyor Metal Detector Machine. In conclusion, our Metal

Sputtering Targets are highly precise, reliable, and of the highest

quality. They are suitable for a wide range of applications in

various industries, including electronics, optics, and aerospace.

Contact us today to learn more about our Metal Sputtering Targets

and how they can benefit your business.

Features:

- Product Name: Metal Sputtering Target

- Technique: Forged And CNC Machined

- Surface: Polished, Anodizing

- Purity: 99.99%

- Surface Finish: Polished

- Thickness: 10-600mm

- Industrial Metal Detector Conveyor

- Alloy Steel Metal

Technical Parameters:

| Parameter | Value |

|---|

| Substrate Compatibility | Customized |

| Technique | Forged and CNC Machined |

| Surface Finish | Polished |

| Target Configuration | Single or Multiple |

| Material | Metal |

| Thickness | 10-600mm |

| Target Bonding | Indium |

| Density | Customized |

| Purity | 99.99% |

| Forming Process | Hot Isostatic Pressing(HIP) |

Applications:

1. Semiconductor Industry: Metal sputtering targets are essential in the semiconductor

industry for the deposition of thin films on silicon wafers. These

thin films are used to create transistors, capacitors, and other

electronic components. The metal sputtering targets are used in

physical vapor deposition (PVD) systems to deposit the thin films

on the silicon wafers. The targets are usually round in shape,

polished to a high surface finish, and have a thickness of

10-600mm.

2. 3D Printing: Metal sputtering targets are also used in 3D printing to produce

metal parts. The metal targets are melted using a laser or electron

beam to produce 3D printing metal powder. The powder is then used

to print metal parts layer by layer. The metal sputtering targets

used for 3D printing are usually customized according to the

specific metal required for the parts.

3. Automotive Industry: Metal sputtering targets are used in the automotive industry for

the deposition of thin films on car windows. The thin films are

used to reduce heat and glare from the sun. The metal sputtering

targets are used in PVD systems to deposit the thin films on the

car windows. The targets are usually round in shape, polished to a

high surface finish, and have a thickness of 10-600mm.

4. Hand Held Metal Detector: Metal sputtering targets are used in hand-held metal detectors

used for security screening. The targets are used to create a

magnetic field that interacts with metal objects. The interaction

produces a signal that is detected by the hand-held metal detector.

The targets used for hand-held metal detectors are usually round in

shape and have a thickness of a few millimeters.

5. Freefall Metal Detector: Metal sputtering targets are also used in freefall metal detectors

used in the food industry. The targets are used to create a

magnetic field that detects metal contaminants in food products.

The targets used for freefall metal detectors are usually round in

shape and have a thickness of a few millimeters.

Metal sputtering targets can be configured as single or multiple

targets depending on the requirements of the application. The

density of the targets can also be customized according to the

specific metal required for the application. The targets are

usually made of high-purity metals such as gold, silver, platinum,

and copper.

Customization:

Support and Services:

Our Metal Sputtering Targets are manufactured with high purity raw

materials using advanced processes to ensure consistent quality and

performance. We offer a wide variety of target sizes, shapes, and

materials to meet your specific requirements.

Our technical support team is available to assist with any

questions or issues you may encounter during the installation,

operation, or maintenance of our sputtering targets. We also

provide comprehensive training for your team to ensure proper

handling and usage of our products.

In addition, we offer a range of services to support your

sputtering process, including custom target design and fabrication,

target bonding, and target recycling. Our team of experts can work

with you to develop a customized solution that meets your unique

needs and budget.