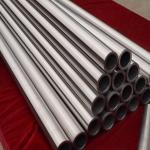

Dia19.05mm Gr1 Welding Titanium Pipe For Heat Exchangers And Pressure Vessels

|

|

OD 19.05mm weld titanium exhaust pipes for Heat Exchangers and Pressure Vessels

Porosity problems in welds Porosity is a common problem when welding titanium and titanium

alloys. The root cause of stomata is the result of the effects of

hydrogen. The formation of pores in the weld metal mainly affects

the fatigue strength of the joint. The main technological measures to prevent pores are: (1) The protection of neon gas should be pure, and the purity

should not be less than 99.99% (2) Thoroughly remove organic matters such as scale oil on the

surface of the welding piece and the surface of the welding wire. (3) Apply good gas protection to the molten pool, control the flow

and velocity of argon gas, prevent turbulence, and affect the

protection effect. (4) Correctly select the welding process

parameters, increase the use of the deep pool residence time and

the right to use the bubbles to escape, which can effectively

reduce the pores. Application Titanium tube light weight, high strength, excellent mechanical

properties. It is widely used in heat exchange equipment, such as

tube heat exchanger, coil heat exchanger, serpentine heat

exchanger, condenser, evaporator and pipeline. Many in the nuclear

industry use titanium tubes as standard for their units. Details :

FAQ 1. Are you the manufacturing or trading company? Real manufacturing company, started from 2001, nearly 20 years. With 2 sales teams for foreign trading business, started from 2008, more than 10 years experiences. 2. Do you have a dedicated R & D team? Can you design a product for us? We have a dedicated technical team responsible for research and development. But most of titanium fittings are standard, we can follow ASTM or other you asked. 3. Can you provide samples? Is there a charge? Samples can be provided for a fee. 4. What is your payment method? We can accept T / T, LC, trade assurance order from alibaba.com. Samples are 100% prepaid. Orders for mass production are below 1000 USD, 100% prepaid, above 1000 USD, 30% prepaid, and 70% paid before delivery. 5. How long is your delivery time? Inventory samples: within 3 working days Products for bulk orders: 25-30 days under normal circumstances. 6. After-sales products, how to deal with problems? Based on our statistics for each year, the probability of problems with titanium products is around 0.8%. There are two main reasons for the problem: 1) Among the products that have problems, 93% are misplaced in pre-sales communication, and the product that the customer needs is not really clear. 2) 5% is an unexpected situation and the extension of the construction period. 3) 2% is the problem of transportation and packaging. During long-distance transportation, the packaging is damaged and the surface is damaged. 7. What is your company's response to the product in question? 1) Verify and blame for pre-sales communication issues. Compensation is handled according to the proportion of liability. 2) We are 100% responsible for problems caused by damaged packaging during transportation. Tag:titanium tube ,titanium pipe ,weld titanium exhaust pipe |

||||||||||||||||||||||||||

| Product Tags: Gr1 welding titanium pipe Heat Exchangers welding titanium pipe Pressure Vessels welding titanium pipe |

|

Annealed Titanium Welded Pipe Custom Lengths per ASME B36.19 |

|

Annealed GR5 ASTM B862 Titanium Welded Tube For Titanium Pressure Vessels |

|

Heavy Wall Black Welded Steel Pipe Alloy Steel Seamless Pipes with X Ray Inspection OD 114.3mm |

|

Titanium Pipe And Tube Forged With Bending And Welding ASME B36.19 ASTM B862 Standard |

|

ASME B36.19 ASTM B862 Certified Heavy Duty Titanium Pipe |

|

Industrial Stainless Steel Welded Tube Production Standards ASME B36.19 ASTM B862 |