Titanium Felt Platinum Coating Anode For Hydrogen Fuel Cell Gas Diffusion Layer

|

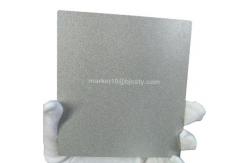

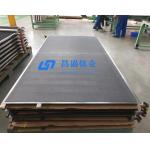

Titanium Felt Platinum Coating Anode For Hydrogen hFuel Cell Gas Diffusion LayerTitanium felt anode gas diffusion layer, sintered titanium felt as substrate for platinum catalyst deposition. The minimum thickness is 0.25mm, the porosity is 50-70%, and the structure is more conducive to gas-liquid mass transfer, with platinum coating and titanium felt substrate firmly combined, with stable performance. Platinum coating Titanium Anode has good electrocatalytic activity and corrosion resistance, and become an anode material of choice in many fields.

Coating Material--Platinum*Purity: 99.99% *Precious metal content: ≥ 21.48 g/㎡ *Coating Thickness: 0.5μm - 15 μm *Features of Platinum: Excellent corrosion resistance, electrical

conductivity and catalytic activity. Substrate Material: Sintered Titanium Fiber FeltTitanium fiber felt is the best material for PEMFC fuel cell industry. It is made from micron titanium fiber through special laying process and

special high temperature vacuum sintering process. *Felt Thickness: 0.25mm - 5.0mm (0.25mm, 0.3mm, 0.4mm, 0.5mm, 0.8mm, 1.0mm, etc,.) *Porosity: 30% to 90% *Length & Width: max. 1200mm *Shape: Square, Rectangular, Circle, Irregular shapes, custom

shape. *Features: high porosity and high specific surface

area, strong oxidation resistance, good temperature and

pressure resistance, good gas permeability, water permeability,

light weight. Technical Parameter for Titanium Felt Platinum Coating Anode

Working Current: < 8000 A/m2 Workmanship: Plating Coating Material: Pt Noble Metal Content: ≥ 21.48 g/m2 Coating Thickness: 0.3-15μm Temperature: < 80℃ PH Value: 1-12 Electrochemical performance and life test

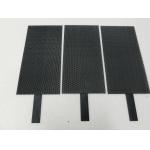

Features of Pt Plated Titanium Anode1. Platinum electrode has strong corrosion resistance and high catalytic activity. 2. High oxygen evolution potential, low hydrogen evolution potential, not only excellent anode material, but also excellent cathode material. 3. High current efficiency, corrosion resistance, can reverse pole. 4. Pt layer has good ductility, so that the anode has good bonding force. Applications of Platinized Titanium AnodePEM electrolysis, Electrolysis of metal, galvanized steel plate,

electrolytic preparation of ionized water, electrolytic chemical

preparation of perchlorate and hypochlorite, electroplating

industry, cathodic protection, seawater desalination, organic

electrolytic synthesis, descaling sterilization and other fields. Why Choose us as your anode supplier?1. Processing according to drawing, support customization 2. High quality assurance 3. On-time delivery 4. Information confidentiality 5. Stable process 6. Repair and re-plating are provided The packaging shall protect the platinum-plated surface to avoid

strong bending or bending of electrodes. The packaging shall be

placed in wooden cases and filled with foam plastic which shall not

be loose. Bespoke Titanium Anode Tags: Hydrogen Fuel Cell titanium fiber felt anode, Gas Diffusion Layer electrode, Pt Platinum coating titanium plate

|

||||||||||

| Product Tags: Platinum Coating Anode Titanium Felt Cell Gas Diffusion Layer Platinum Anode Platinum Coating Titanium Electrode |

|

Not Powder Titanium Anodes For Aluminum Foil Forming In EV Charging Stations 9-18 Months Design Life |

|

Sodium Hypochlorite Generator for Disinfection / Water Treatment |

|

BM 2.7 4Gen Anode Cell Titanium For Chlor-alkali (chlorine Alkali) Industry |

|

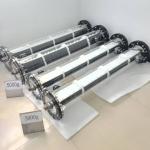

Application Of Titanium Bipolar Plates And Mono Plates In Hydrogen Energy Systems |

|

Ru-Ir/Ir-Ta Gr1 Titanium MMO Coated Tubular Anode 99.6% Ti Content with Sample |

|

Electrolyzer accessories Anode and cathode cell Inlet distribution pipe for Chlor-alkali plant |