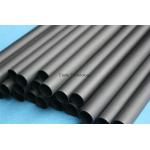

Dsa Titanium Anode Dimensionally Stable Anode For Electrochemistry Electrometallurgy

|

Detailed Product Description

dsa coating titanium anode Dimensionally Stable Anode for electrochemistry electrometallurgydsa coating titanium anode(Dimensionally Stable Anode), also known as the Dimensionally Stable anode, is a new type of insoluble anode material developed in the late 1960s. Classification: |

Classification | platinum, graphite and lead alloy anode |

Application | electrochemistry,electrometallurgy.include: chlor-alkali industry, chlorate production, hypochlorite production, perchlorate production, persulfate electrolysis, electrolytic organic synthesis, electrolytic extraction of non-ferrous metals, electrolytic silver catalyst production, electrolysis of copper foil, electrolytic oxidation recovery of mercury, hydroelectrolysis, preparation of chlorine dioxide, hospital sewage treatment, electroplating plant cyanide wastewater treatment, domestic water And food appliances disinfection, power plant cooling circulating water treatment, dyeing and finishing wastewater treatment, industrial water treatment, electrolytic acid-base ionized water, copper plate galvanized, rhodium plating, palladium plating, gold plating, lead plating, electrodialysis desalination of seawater, electrodialysis method of tetramethylammonium hydroxide, molten salt electrolysis, battery production, cathodic protection, the production of anode foil, aluminum foil anodizing And so on |

Product Show:

Baoji city changsheng can provide Life Test

Coating X-Ray Test

Coating Thickness Test

Helium Leak Detection Test,

Contact Resistance Test

Performance Test and other test.

Application:

DSA coated titanium anode is mainly used in electrochemistry and

electrometallurgy.

DSA Application fields of coated titanium anode include:

chlor-alkali industry, chlorate production, hypochlorite

production, perchlorate production, persulfate electrolysis,

electrolytic organic synthesis, electrolytic extraction of

non-ferrous metals, electrolytic silver catalyst production,

electrolysis of copper foil, electrolytic oxidation recovery of

mercury, hydroelectrolysis, preparation of chlorine dioxide,

hospital sewage treatment, electroplating plant cyanide wastewater

treatment, domestic water And food appliances disinfection, power

plant cooling circulating water treatment, dyeing and finishing

wastewater treatment, industrial water treatment, electrolytic

acid-base ionized water, copper plate galvanized, rhodium plating,

palladium plating, gold plating, lead plating, electrodialysis

desalination of seawater, electrodialysis method of

tetramethylammonium hydroxide, molten salt electrolysis, battery

production, cathodic protection, the production of anode foil,

aluminum foil anodizing And so on. Widely used in chemical

industry, metallurgy, water treatment, environmental protection,

electroplating, electrolytic organic synthesis and other fields.

In recent years, the application of DSA coated titanium anode has

been a new trend in the surface treatment industry. For example,

some nanomaterials are added to the coating to improve the

electrocatalytic activity of DSA anode. For example, in some

specific plating solution, the oxygen evolution potential of DSA

coating can be adjusted to inhibit the production of some impurity

ions and ensure the stability of the plating solution. With the

further research of DSA coated titanium anode, its application

prospect will be more and more broad.

Tag: dsa titanium anode,dsa coating titanium anode,dsa titanium anodes

Related Products

|

Not Powder Titanium Anodes For Aluminum Foil Forming In EV Charging Stations 9-18 Months Design Life |

|

Sodium Hypochlorite Generator for Disinfection / Water Treatment |

|

BM 2.7 4Gen Anode Cell Titanium For Chlor-alkali (chlorine Alkali) Industry |

|

Application Of Titanium Bipolar Plates And Mono Plates In Hydrogen Energy Systems |

|

Ru-Ir/Ir-Ta Gr1 Titanium MMO Coated Tubular Anode 99.6% Ti Content with Sample |

|

Electrolyzer accessories Anode and cathode cell Inlet distribution pipe for Chlor-alkali plant |

Email to this supplier