Titanium anode for ammonia nitrogen wastewater treatment Ir series coating

|

Titanium anode for ammonia nitrogen wastewater treatmentAmmonia nitrogen wastewater mainly comes from chemical fertilizer,

coking, petrochemical, pharmaceutical, food, landfill, etc. A large

amount of ammonia nitrogen wastewater discharged into water bodies

not only causes eutrophication of water bodies, resulting in black

and smelly water bodies, increasing the difficulty and cost of

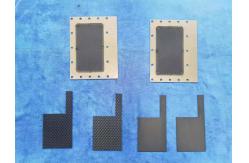

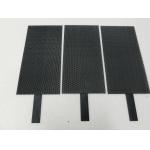

water treatment, and even toxic effects on people and organisms. Overall, the use of a titanium anode in the treatment of ammonia nitrogen wastewater can be an effective and efficient method for reducing the concentration of pollutants in the wastewater. However, the specific electrochemical process used will depend on the specific characteristics of the wastewater and the desired treatment outcomes. Here is some technical data for titanium anode used in ammonia nitrogen wastewater treatment:Material:

Physical Characteristics:

Electrochemical Characteristics:

Environmental Characteristics:

Applications:

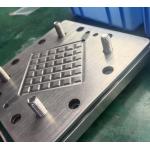

Note that the technical data provided is just an example, and specifications may vary depending on the manufacturer and specific application. It's important to consult with our technical team to ensure that the titanium anode is appropriate for the specific wastewater treatment system. Our control and Test :(1) Main quality indicators: titanium substrate, precious metal

ratio, accelerated life, coating binding force to the titanium

substrate(coating adhesion) Test we done:

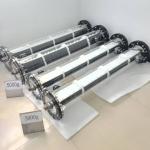

Here is an example of a real-world application of titanium anodes for ammonia nitrogen wastewater treatment:Case Study: Wastewater Treatment Plant in China

A wastewater treatment plant in China was experiencing difficulties in treating ammonia nitrogen in their wastewater effluent. The plant was using traditional biological methods for treatment, but the process was not efficient in removing high levels of ammonia nitrogen. To address the issue, the plant installed a new electrochemical system using titanium anodes with an IrO2 coating. The system utilized a process called electrooxidation, which applies a voltage to the electrodes to generate active oxidizing agents that react with ammonia nitrogen and other pollutants in the wastewater. The electrochemical system was designed with multiple titanium anodes in a reactor tank, and the wastewater was continuously circulated through the reactor to ensure effective treatment. The process allowed for complete removal of ammonia nitrogen and other pollutants, and the treated wastewater met the local discharge standards. The use of titanium anodes with an IrO2 coating proved to be an effective solution for the plant's ammonia nitrogen treatment needs. The electrochemical system was able to achieve high removal rates of ammonia nitrogen, while also being cost-effective and requiring low maintenance. Overall, this case study highlights the potential benefits of using titanium anodes for ammonia nitrogen wastewater treatment, particularly in situations where traditional treatment methods are not effective. |

||||||||||||||||||||||||||||||||

| Product Tags: COD Degradation Titanium Cathode Plate High Iridium Titanium Cathode Plate IrO2 Titanium Electrode Anode | ||||||||||||||||||||||||||||||||

|

Not Powder Titanium Anodes For Aluminum Foil Forming In EV Charging Stations 9-18 Months Design Life |

|

Sodium Hypochlorite Generator for Disinfection / Water Treatment |

|

BM 2.7 4Gen Anode Cell Titanium For Chlor-alkali (chlorine Alkali) Industry |

|

Application Of Titanium Bipolar Plates And Mono Plates In Hydrogen Energy Systems |

|

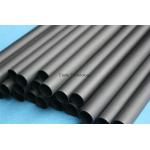

Ru-Ir/Ir-Ta Gr1 Titanium MMO Coated Tubular Anode 99.6% Ti Content with Sample |

|

Electrolyzer accessories Anode and cathode cell Inlet distribution pipe for Chlor-alkali plant |