Composite Grid Plate Galvanized Grid Plate Composite Steel Grid

Plate For Walkway Industrial Plant Grid Plate

| orgin | Anping |

| grating name | composite grating plate |

| specification | as required |

| steel plate | checkered steel plate |

| steel plate thickness | 3mm 4mm 5mm 6mm |

| material | as required |

| surface | galvanizing |

| application | Walkway or platform |

| transport | shipping |

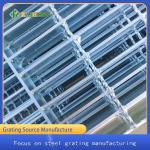

composite steel grating Introduction

Composite steel grating plate is an extension of conventional

grating plate. A 3-6mm checkered steel plate is welded on the steel

grating plate formed by pressure welding of flat steel and cross

bar, and then the composite steel grating plate is formed, and then

galvanized to become the finished product of composite steel

grating plate.

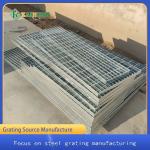

composite steel grating plate Advantages

1: Bright surface beautiful appearance

2: Strong corrosion resistance

3: High strength, light structure

4: Ventilation, daylighting,anti-skid, good explosion-proof

performance heat dissipation, .

5: Easy maintenance,snow, ponding, No dirt, rain,

self-cleaning

6: Convenient for disassembly and installation .

Construction site installation method of composite steel grating

plate

1. Directly weld the steel grating or step plate on the supporting

steel structure, and brush the welding part with two coats of

galvanized powder paint.

2.Stainless steel mounting clip or bolt connection and other

fastening methods can be provided as required.

3. It is installed with a special installation clamp for multi grid

steel grating, which does not damage the galvanized layer and is

convenient for disassembly and assembly. Each set of mounting

clamps includes an upper clamp, a lower clamp, an M8 round head

bolt and a nut.

4. Pay attention to the firm and reliable installation during

installation, and check frequently to prevent the installation

clamp from loosening and falling off. Weld or add rubber pad near

the vibrating steel grating.

5. The installation clearance of steel grating is generally 100mm.