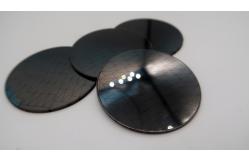

CTSTC High Speed Continuous PCD Laser Cutting Abrasion Resistance

|

|

Fiber Laser Cutting Service For Polycrystalline Diamond Compact Tools 2D Shape Quick Details 1. Narrow kerf ≦0.06mm 2. Multiple intelligent sensor modules greatly improve personnel safety and effect of equipment protection 3. Many years practice in laser cutting service 4. Diamonds are faceted and have a smooth surface 5.High speed and efficiency

Description: Our company product a number if diamond tool production lines,laser cutting machines,vacuum welding machines. Polycrystalline Diamond Cutting Tools has higher wear resistance than tungsten steel tool, and the theoretical value is 50-200 times that of tungsten steel tool. Consider abrasion resistance and tipping resistance, high-speed continuous cutting. Fit for rough machining and semi-finishing of high-hardness alloy cast iron, high nickel chromium, high ferrochrome and other materials. Fit for rough machining and semi-finishing of gray cast iron and nodular cast iron.

Example

|

||||||||||||||||||||||||

| Product Tags: high speed PCD Laser Cutting continuous PCD Laser Cutting |

|

Fiber PCD Laser Cutting Service For Cubic Boron Nitride Cutting Tools |

|

1.6mm PCD Laser Cutting Service For Polycrystalline Diamond Cutting Tools |

|

600mm/Min CNC Metal Cutting Service For Cubic Boron Nitride Cutting Tools |

|

High Hardness PCD Laser Cutting 3.2mm Thickness For Diamond Tools |

|

High Efficiency PCD Laser Cutting For Diamond Cutting Tools 3.2mm |

|

2D Shape Narrow Kerf PCD Laser Cutting For Cubic Boron Nitride Tools |