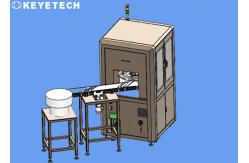

Pharma Medical Plastic Parts Appearance Visual Inspection System

|

|

Inspection Principle The system transports the samples stably and orderly to the predetermined workstation, and then transmits the captured high-pixel sample images to the image processing software through the industrial camera. After comparing with the standardized samples, the defects of defective products and good products are distinguished, and the corresponding pneumatic components are controlled. Remove defective products.

The software will open sample comparison standards, and production personnel at the customer site can control the comparison accuracy and select the accuracy standard that best suits their own production conditions, thereby controlling the defective rate.

Equipment Features

Algorithm Features

After-sale Service The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation. After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance. |

|||||||||||||||||||||||

| Product Tags: OEM Product Appearance Inspection Machine Camera Inspection System 220V Intelligent Camera Inspection System |

|

GPU Computing Ai Inspection System For Multi Specification Flip Cap |

|

CCD Camera Cap Sorting Machine With AI Deeping Learning Algorithm |

|

Edible Oil Bottle Cap Automation Products Closure Optical Sorting Machine |

|

Air Compressed Online Reject Defect Product Water Cap Vision Detection Machine |

|

High Precision 0.1mm Cap Vision Detection System 5kw-7kw Power SS 304 Material |

|

Water Cap Closures Visual Inspection System with 6 CCD Industry Cameras |