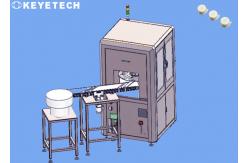

Tetra Pak Cap Inspection System with HMI Automated Quality Control

|

Product Description:Cap Inspection System Cap Inspection System is an advanced closure checking system which is designed to accurately detect and evaluate the quality of caps and closures. It is capable of voltage/current adjustment to meet national standard, and provides excellent data statistics and inspection precision up to 0.1mm. Furthermore, it offers high inspection speed from 600pcs/min to 2000pcs/min and comes with a one year warranty. The Cap Inspection System is considered as an ideal cover examining system for a wide range of industries. With its robust and reliable closure inspection software, it can be easily integrated into existing production lines. The system is also capable of detecting a variety of defects such as broken or missing caps, incorrect lid color, incomplete assembly, and other irregularities. The Cap Inspection System is the perfect solution for manufacturers looking for a reliable and cost-effective cap closure checking system. With its superior performance, it provides maximum value for its users, allowing them to achieve the highest quality standards in their production. Features:

Technical Parameters:

Applications:KEYE TECH's KVIS-C Cap Inspection System, with CE/ISO 9001/UL

certification, is made in China and offered with a minimum order

quantity of 1 SET. This lid auditing system is highly accurate,

with an inspection accuracy of 99.8%, and is suitable for

inspecting caps and closures with an inspection precision of 0.1mm.

It works with an air compressed range of 0.5Mpa-0.8Mpa and can

inspect up to 2000 pcs per minute. It is made with SS 304 material

to ensure durability and long-term use. The price is negotiable and

the delivery time is 6-8 weeks. The packaging is plywood carton and

payment terms are TT, L/C. The supply ability is 80 sets per month. Support and Services:Cap Inspection System Technical Support and Services We are committed to providing the highest level of customer service and technical support for our Cap Inspection System. Our technical support team is available to answer your questions and provide technical assistance to ensure your continued success. We offer free technical support by phone, email, and webchat, as well as an online knowledgebase of frequently asked questions and answers. Our knowledgeable technicians are available to help you troubleshoot any issues you may have with the system. We also offer a variety of additional services, such as on-site installation and training, as well as custom programming and integration services. Please contact us to find out more about our services and how we can help you get the most out of your Cap Inspection System. Packing and Shipping:Packaging and Shipping for Cap Inspection System The Cap Inspection System is packaged for shipping in a sturdy corrugated cardboard box with protective material. The box is designed to contain components securely, and is labeled with product information and instructions for use. The box also includes an outer label with the sender's address and the recipient's address. The Cap Inspection System is shipped via air freight, with an expected delivery time of 7-10 business days. The shipment includes tracking information which can be used to monitor the progress of the shipment. |

|

Packaging Inspection Equipment For PP Plastic Disposable Food Containers |

|

Straw Defective Product Inspection Machine with Automatic Labeling System |

|

21 Inches Touch Screen Ai Inspection System for Paper Cup Surface Defect Detection |

|

Instant Noodles Bowl Appearance Defect Detection Equipment 300pcs/Min |

|

Intelligent Machine Vision Inspection Systems Aoi Machine For Yogurt Cup |

|

3D HMI Surface Inspection Equipment Machine For Ice Cream Plastic Cup 300pcs/Min |