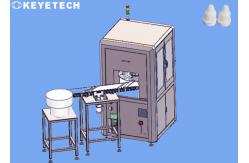

Product Description:

The Cap Inspection System is an efficient and comprehensive utility

for examining, checking and validating the closures of caps. With

its high-performance Human Machine Interface (HMI), it offers a

reliable and accurate inspection accuracy of 99.8%, deep inspection

depth, and a fast inspection speed of 600-2000 pcs/min. requiring

only 0.5-0.8Mpa air compressed. It is the perfect choice for bottle

cap examining, closure checking and validation. By using this Cap

Examining Utility, companies can get the most reliable and

comprehensive results for their cap closure checking system.

Features:

- Product Name: Cap Inspection System

- Application: Cap Closure Inspection

- Air Compressed: 0.5Mpa-0.8Mpa

- Voltage/Current: Adapt To National Stardard

- Inspection Depth: Deep Inspection

- Inspection Speed: 600pcs/min - 2000pcs/min

- Lid Auditing System

- Closure Inspection Software

- Cover Examining System

Technical Parameters:

| Parameter | Details |

|---|

| Data Statistics | Support |

| Weight | 350kg |

| Software | Self-develped |

| Air Compressed | 0.5Mpa-0.8Mpa |

| Application | Cap Closure Inspection |

| Display Screen | HD Touch Screen |

| Inspection Accuracy | 99.8% |

| Inspection Precision | 0.1mm |

| Inspection Area | 360 Degree Inspection |

| Camera Brand | KEYE OEM |

Applications:

KEYE TECH's KVIS-C Cap Examining Utility is a specialized closure

inspection software that ensures the quality and safety of all caps

and closures. The system is CE/ISO 9001/UL certified and is made of

superior SS 304 material. It comes with self-developed software and

is capable of inspecting up to 2000 caps per minute with air

compressed between 0.5Mpa-0.8Mpa. The minimum order quantity is 1

SET and the delivery time is 6-8 weeks. Price is negotiable and

payment terms include TT, L/C. The packaging for the system is

Plywood Carton and the warranty is 1 year. KEYE TECH is confident

in the quality of the KVIS-C Cap Examining System, and provides a

supply capability of 80 SET per month. The KVIS-C Cap Examining

System is the perfect tool for all quality assurance processes

related to caps and closures.

Support and Services:

Cap Inspection System provides technical support and service to our

customers. Our services include:

- 24/7 technical support

- Remote diagnostics and troubleshooting

- On-site maintenance and repair

- Software updates and upgrades

- Training and education

Packing and Shipping:

The Cap Inspection System should be packaged and shipped with great

care and attention. All components should be securely wrapped and

cushioned to prevent any damage during transport. The box should be

marked with the name of the product and the shipping address. The

box should also be clearly labeled with any additional instructions

as to the handling of the product. To ensure that the product

arrives in good condition, it should also be shipped with an

appropriate level of insurance.