High Grade Quality Bottle Measurement System with Inspection Accuracy 99.5%

|

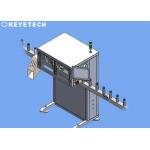

Product Description:The Bottle Inspection System is an advanced measuring solution that ensures the quality and accuracy of bottles. It is a fully automated system, featuring a PLC control system, touch screen display, and stainless steel construction. It is designed to provide a fast, efficient, and reliable solution to bottle evaluation, verification, and measurement. The system has a dimension of 3000x1200x1800mm and uses air blowing as its rejection method.

The Bottle Inspection System is a powerful and reliable tool for bottle production, offering a comprehensive and accurate evaluation of the bottles. It is an ideal choice for any bottle producer looking for an efficient and reliable system to measure the dimensions, weight, and other features of their bottles. With its advanced PLC control system and stainless steel construction, the Bottle Inspection System is a reliable and accurate solution for any bottle producer. The Bottle Inspection System is a comprehensive evaluation and measurement system that is designed to help bottle producers ensure the quality and accuracy of their bottles. It is a powerful, reliable, and comprehensive system that offers a fast, efficient, and reliable solution for bottle verification, measurement, and evaluation. With its advanced PLC control system, touch screen display, and stainless steel construction, the Bottle Inspection System is an ideal choice for any bottle producer looking for a reliable and accurate system to measure the dimensions, weight, and other features of their bottles. Features:

Technical Parameters:

Applications:The Bottle Inspection System produced by KEYE is a perfect solution for bottle verification, evaluation and quality control. With the model number KVIS-B, it is certified with CE/ISO and the minimum order quantity is 1 SET. Price is negotiable, and the package is plywood carton. Delivery time is 6-8weeks and payment terms is T/C. The supply ability is 5 SET PER MONTH. Power consumption is 500W and the control system is PLC. The dimension is 3000x1200x1800mm and the power supply is AC220V/50Hz. The inspection item includes Cap, Label, Bottle Body, Etc. Support and Services:Our Bottle Inspection System provides comprehensive technical support and services to ensure that our customers are able to use our products with confidence and ease. We provide:

Our experienced technical staff is always available to help you with any problems or questions you may have about our Bottle Inspection System. Packing and Shipping:Packaging and Shipping for Bottle Inspection System Bottle Inspection System is packaged in a box containing all the necessary components required for it to be operational. The box is designed to withstand the rigors of shipping and has a handle for easy handling. The box is secured with a custom made tamper-proof seal to ensure that the contents remain intact, secure, and undamaged during the shipping process. The Bottle Inspection System is shipped via a reliable, reputable courier service in order to ensure that the product reaches its destination safely and in a timely manner. The system is tracked throughout the delivery process to ensure visibility and delivery confirmation. |

|

Surface Defective Inspection System Rejection Machine For Juice Bottles |

|

Automatic Defect Detection System Leak Detector For Filling Cocktail Bottles |

|

Impurity Visual Quality Inspection Machine for Cosmetic Bottle Packagings |

|

Plastic Pharmaceutical Bottle Inspection Machine High Accuracy Sorting |

|

Real Time Detection System For Bottle Surface Defects Based On Machine Vision |

|

Real-Time Dairy Empty Bottle Camera Inspection System With Rejection Valve |