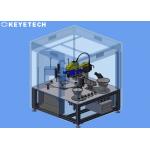

PET Preform Visual Inspection Machine Surface Bubble Oil Stain Defects Detector

|

|

PET Preform Visual Inspection Machine Surface Bubble Oil Stain Defects Detector

Inspection principle Through the preform unscrambling device (this solution does not include the preform unscrambling machine), the preforms are stably and orderly transmitted to a specific station, and then the high-pixel sample images captured by the industrial camera are transmitted to the image processing software, and the good products are judged after system analysis and defective products, and control the corresponding pneumatic components to remove defective products, and finally collect qualified products.

Vision solutions The design scheme uses 10 sets of high-resolution industrial cameras and high-performance strobe light sources to conduct all-round visual inspection for the appearance defects of preform products. The inspection speed is 150-600 pieces/minute, and the equipment can operate 7*24 hours a day. Unqualified products can be automatically removed online. The whole set of testing equipment includes mechanical parts, visual electronic hardware and testing system software. The testing machine can be connected to the unscrambling machine or the automatic conveying mechanism for online use, and can be connected to the upstream and downstream production equipment according to the specific production needs of the customer's site.

Inspection Standards

Black spots, stains, and hair will be analyzed and processed according to the black spot detection index. The difference between the gray value of this item must be greater than 40, which can be effectively detected. If the sample has transparent oil stains or light-colored black spots, and the gray value contrast difference value is low (less than 40), the detection effect cannot be achieved. Due to the complex structural features of the product, in the actual inspection application, there will be a certain detection blind spot in the structural overlapping area of the plane lens imaging, and the image cannot be collected within this blind spot, so it cannot be effectively detected.

After-sale service The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation. |

|

Top Seal, Body, Injection Gate Inspection and Sorting Machines for PET Preforms |

|

Computer Vision System for Preform Feeding Orientation and Defect Detection |

|

CSD PET Preform Vision Inspection System Optical Camera Checking Machine |

|

AI Based Quality Control Vision Inspection System for Plastic Bottles Preforms |

|

Easy Maintenance and Operation Visual Inspection System For PET Preforms |

|

CCD Visual Defect Inspection Machine for Transparent Colored PET Preform |