On Line Detector Machine For Bottle Closure Laundry Detergent Spout Cap

|

|

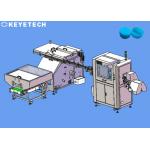

On-line Detector Machine for Bottle Closure Laundry Detergent Spout Cap

Inspection standards

Inspection principle The equipment is composed of a vibrating plate unscrambling machine and a visual inspection machine; the lids are sorted into columns by the "cap unscrambling machine" in a stable and orderly manner, and then enter the "visual inspection machine" inspection station. There are two stations inside the "visual inspection machine" , the camera at the first station is arranged under the upper adsorption conveyor belt, the cover is sucked by the adsorption belt, and the camera takes pictures from bottom to top to collect the concave area of the lower cover. The camera at the second station is arranged above the conveyor belt, with 8 cameras (2 layers*4 cameras) and 1 camera on the top to take pictures of the top surface of the cover, the side of the upper cover, and the side of the lower cover. The camera transmits the captured image to the processing software, compares and analyzes it with the standardized sample to determine good products and defective products, and controls the corresponding pneumatic components to eliminate the defective products, and finally collects qualified products.

Inspection details The design scheme uses 10 sets of high-pixel area array industrial cameras and high-performance strobe light sources to conduct comprehensive inspections on the concave surface of the lower cover, the side of the lower cover, the side of the upper cover, and the top surface of the upper cover. The entire set of equipment is designed and tested The speed is 60 pieces/minute, and the equipment can operate 7*24 hours a day. Unqualified products are automatically eliminated online, and qualified products are counted and packed.

Equipment features:

Company profile KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Detergent Spout Cap Detector Machine Laundry Spout Cap Detector Machine |

|

Automatic Optical Inspection Machine for Medical Plastic Industry Accessories |

|

Plastic Injection Molded Part Quality Checking Vision Sorting Machine |

|

Professional Vision Supplier Optical Inspection Systems for Pharma Euro Cap |

|

AI Based Mineral Water Cap Optical Vision Sorting Machine with Feeding Device |

|

SS 304 Vision Inspection Machine Applications Surface Flash, Short Mold, And Black Spot |

|

Dropper Cap Camera Visual Inspection Machine HMI Touch Screen Support |