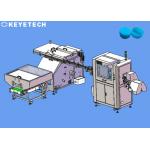

Dosing Cap Visual Inspection Machine with Online Defect Product

Reject Function

Inspection standards | Item | Camera | Position | Inspect | Precision | Accuracy | Speed | | KY-PC | 4 | outer side | deformation,size,scratch,different color,filling material,etc. | >0.3mm | 99% | | | 1 | front side | >0.3mm | 100-300

pcs/min | | 1 | bottom side | >0.3mm |

Company Profile

Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national

high-tech enterprise specializing in the application of AI

technology in visual inspection industry. As a leading

manufacturer&Designer, It can provide the most advanced level

AI visual inspection equipment and the customized AI system

solutions of visual imaging, computing power, algorithm, and

automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D

team from top domestic optical research institutes and a core

doctoral team from the USTC, covering the entire technology chain

of optics, electrics, mechanics, algorithm and software. Our

products can be applied in beverage, pharmacy, dairy, wine,

textile, new energy, agriculture and other packaging industries.

Inspection Overview

The design scheme uses high-pixel industrial cameras and

high-performance strobe light sources to conduct all-round visual

inspection for the appearance defects of products. The inspection

speed is 100-300 pcs/min, and the equipment can operate 24 hours a

day. Products can be automatically rejected online.

The whole set of vision machines includes mechanical parts, visual

electronic hardware and vision system software. The entrance and

exit of the inspection machine can be integrated with the

customer's on-site conveyor line, and can be connected with

upstream and downstream production equipment according to the

specific production needs of the customer's site.

Software Function - Enabling and disabling the system detection function

- Detection index parameters and accuracy adjustment

- Template sampling and saving, storage and retrieval of sample

information

- Camera screen calibration function

- Real time production information display of the system

(qualification rate, total output, speed, etc.), browsing of

historical production information, export and storage functions

- Manage permissions based on login account (example, disabling

parameter adjustment for general operation users)

- Operation and adjustment of the mechanical part of the system (If

the transmission device is turned on, adjust the alarm signal)

Operation Parameters | Power | 5.0-7.0Kw | Voltage/Current | Local standard | | Ambient Temperature | -20℃ ~ 60℃ | Ambient humidity | Less than 50% | | System Language | Chinese / English | Mechanical | Carbon Steel / SS 304 | | Total Weight | About 650Kg | Dimension | As actual drawings |

Configuration List | Description | Model | Unit | Q’ty | Remark | | Industrial Cameras | KeyeTech | Set | 6-8 | China | | Lenses | KeyeTech | Set | 6-8 | China | | LED Light Source | KeyeTech | Set | 3 | Taiwan, China | | Photoelectric Sensor | SICK | Pair | 1 | Germany | | Electromagnetic Valve | SMC | PC | 1 | Japan | | Industry Power | Mean Well | Set | 3 | Taiwan, China | | Main Control Board | KEY-PC-2.1 | PC | 1 | China | | AI Computing Unit | KeyeTech EBS-1684X | Set | 2 | China | | Pollution Filter | KeyeTech AC30D-02G-A | Set | 1 | China | | HID Touch Screen | AOC 21’ | Set | 1 | China | | AI Algorithm System | KeyeTech KVS-V16.0 | Set | 1 | China | | AI Cloud Platform | KeyeTech | Set | 1 | China | | Big Data Server | KeyeTech | Set | 1 | China | | Operation System | Linux | Set | 1 | China |

Delivery Time

The production cycle of the whole machine is expected to take 60

days. If additional inspection requirements are added or more

adjustment needed, the time will be appropriately extended

accordingly. After the equipment arrives at the customer's site,

our company arranges after-sales personnel to complete installation

and adjustment at the customer's site.

After Sales Service - The seller should complete the creation and debugging of the

product basic algorithm model before the equipment is shipped, also

provide remote assistance after the equipment arrives at the

customer site; and provide buyer with the factory data and

operation manual of equipment.

- Daily operation and maintenance services: Our company provides free

remote operation and maintenance online services. If you need to

upgrade inspection algorithm, provide operational assistance, etc.

- Our company have regular offline training plan every year, so

domestic and foreign clients can send their engineers to

participate (at their own expense). Those who pass the exam can

obtain an industry functional skills certificate.

|