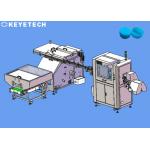

Plastic Accessories CCD Automatic Visual System With Glass Turntable Inspection

|

|

Plastic Accessories CCD Automatic Visual System With Glass Turntable Inspection Equipment features:

Inspection principle Major pharmaceutical companies have very high requirements on the quality of rubber stoppers, and some even require disposable rubber stoppers. In order to ensure the quality of rubber plugs, in addition to testing physical and chemical properties such as heat sources, microorganisms, particles, metal elements, and tensile strength, rubber plug manufacturers also need to conduct comprehensive inspections on the appearance, shape, size, and color difference of rubber plugs. detection. In the production process of rubber stoppers, the rubber stoppers will inevitably have polygons, shearing, collapse, deformation, damage, stains, white spots, dirt, foreign matter, hair, offset, surface wrinkles, poor sol, lack of glue, Bubbles, and other defects. The machine vision detection speed is fast, which can meet the high-speed and high-efficiency production requirements of the production line, and the detection effect is stable, the detection results are very objective and reliable, and the labor cost is reduced.

Vision solutions The rubber plugs are accelerated by adding an air blowing device at the vibrating guide rail of the vibrating plate, so that the two rubber plugs can be spaced apart. The material speed is more unstable, and a stabilizing device is needed. The position of the rubber plug is controlled by adding a stopper device so that the rubber plugs are arranged in an orderly manner. However, after the addition of a stopper device, the position of the rubber stopper can be controlled while the rubber plug itself produces a rotational movement, so that the discharge more stable.

Advantages of CCD inspection

After-sale service The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation. After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

Company profile Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries. |

|||||||

| Product Tags: Automatic Inspection System Modularization Rubber Accessories Automatic Inspection System CCD Automatic Inspection System |

|

Automatic Optical Inspection Machine for Medical Plastic Industry Accessories |

|

Plastic Injection Molded Part Quality Checking Vision Sorting Machine |

|

Professional Vision Supplier Optical Inspection Systems for Pharma Euro Cap |

|

AI Based Mineral Water Cap Optical Vision Sorting Machine with Feeding Device |

|

SS 304 Vision Inspection Machine Applications Surface Flash, Short Mold, And Black Spot |

|

Dropper Cap Camera Visual Inspection Machine HMI Touch Screen Support |