AOI Visual Inspection System For Bottle Cap Gasket Seal Checking

|

Company profile Key Technology relies on the Key Laboratory of Pattern Recognition of the University of Science and Technology of China, and has a high-level doctoral R&D team covering the entire technology chain of optics, mechanics, electricity, computing and software. Through the project practice in the fields of packaging containers, 3C, medicine, textile, food, etc., the KVS-AI software and hardware platform has been created, so that AI technology can be transformed into real productivity.

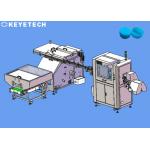

Inspection principle This scheme is designed according to the actual workpiece conditions on site, and the bottle cap gasket is visually inspected to replace manual inspection work. The detection system as a whole integrates visual optical hardware, detection system software, and double pad sensors. The detection equipment is installed online on the production line. The detection speed is 500/min in the absence of occlusion. The equipment can operate 7*24 hours a day, which greatly improves production efficiency.

Application of camera

System composition

Additional functions that Party A needs to add. |

||||||||||||||||

| Product Tags: AOI Visual Inspection System Bottle Cap Seal Visual Inspection | ||||||||||||||||

|

Automatic Optical Inspection Machine for Medical Plastic Industry Accessories |

|

Plastic Injection Molded Part Quality Checking Vision Sorting Machine |

|

Professional Vision Supplier Optical Inspection Systems for Pharma Euro Cap |

|

AI Based Mineral Water Cap Optical Vision Sorting Machine with Feeding Device |

|

SS 304 Vision Inspection Machine Applications Surface Flash, Short Mold, And Black Spot |

|

Dropper Cap Camera Visual Inspection Machine HMI Touch Screen Support |