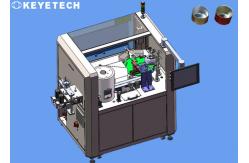

Inspection System For The Quality Control Of Aluminum Caps And Closures

|

Company profile Key Technology relies on the Key Laboratory of Pattern Recognition of the University of Science and Technology of China, and has a high-level doctoral R&D team covering the entire technology chain of optics, mechanics, electricity, computing and software. Through the project practice in the fields of packaging containers, 3C, medicine, textile, food, etc., the KVS-AI software and hardware platform has been created, so that AI technology can be transformed into real productivity.

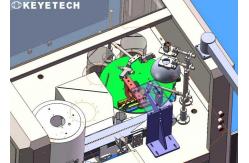

Overview: The overall equipment integrates mechanical mechanism, visual optical hardware and detection system software, rejecting and counting devices for defective products. The products to be inspected are sorted by the vibrating plate (not included in this plan), and are stable and orderly. They are sent to the glass turntable inspection station for sequential inspection. After comparing and analyzing the image processing software with the standardized sample, the good and bad products are judged.

Inspection principle Our company's design scheme adopts 16 sets of high-pixel area array industrial cameras and high-performance strobe light sources, and conducts comprehensive inspections on the top, side, and concave defects of the product. The design inspection speed of the entire set of inspection equipment is 400 pieces/minute , The equipment can operate 7*24 hours a day, and the unqualified products can be automatically eliminated online.

After-sale service The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance. |

||||||||||||||||

| Product Tags: Aluminum Closures Inspection System Aluminum Caps Inspection System | ||||||||||||||||

|

Packaging Inspection Equipment For PP Plastic Disposable Food Containers |

|

Straw Defective Product Inspection Machine with Automatic Labeling System |

|

21 Inches Touch Screen Ai Inspection System for Paper Cup Surface Defect Detection |

|

Instant Noodles Bowl Appearance Defect Detection Equipment 300pcs/Min |

|

Intelligent Machine Vision Inspection Systems Aoi Machine For Yogurt Cup |

|

3D HMI Surface Inspection Equipment Machine For Ice Cream Plastic Cup 300pcs/Min |