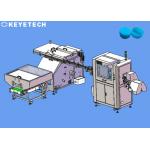

Pharmaceutical Nozzle Caps Visual Inspection Machine With Ai Intelligent System

|

|

Pharmaceutical Nozzle Caps Visual Inspection Machine With Ai Intelligent System

Equipment features

Inspection principle In the packaging process of bottled products, that is, during the capping, labeling, coding, pressing and lifting rings, and packing processes, due to mechanical failures, defects in packaging supplies, etc., defects in the outer packaging of bottled products often occur. The existing detection methods for bottle cap defects of bottled products are all detected by human eyes under light. Manual visual detection is inefficient and has a high rate of false positives. It is very difficult to maintain a stable and accurate detection effect. Coupled with the rise in labor costs in recent years, it is necessary to use machine vision automated inspection to replace traditional inspection methods

Vision solutions The intelligent visual inspection machine for bottle caps independently developed by KEYE TECH is equipped with an AI deep learning system. Repeated training on product defect maps and good products can detect the appearance of products in complex environments in real time. Taking multi-angle and all-round photos, the intelligent system transmits each frame of the captured picture to the on-site computer vision system, analyzes and processes the picture information through automatic picture processing software, and screens out bottle caps with flaws in appearance to realize correctness Automatic online rejection of good products. The software platform of the bottle cap inspection vision system is reasonably constructed, with a friendly interface and easy to use. It can realize remote control. The system can be customized on demand and has good adaptability. Yuzhen bottle cap inspection machine is easy to operate and has three types of manual adjustment, semi-automatic adjustment, and fully automatic adjustment. The automatic bottle cap inspection machine equipment uses a high-performance CCD industrial camera, which can detect a variety of bottle caps.

Company profile KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry. |

|||||||

| Product Tags: Nozzle Caps Visual Inspection Machine Ai Intelligent System Visual Inspection Machine |

|

AI Based Mineral Water Cap Optical Vision Sorting Machine with Feeding Device |

|

SS 304 Vision Inspection Machine Applications Surface Flash, Short Mold, And Black Spot |

|

Dropper Cap Camera Visual Inspection Machine HMI Touch Screen Support |

|

Full Automated AI Dropper Nozzle Plug Vision Inspection Machine |

|

Flip Cap Vision Sorting Machine High Resolution Optical Inspection System |

|

High Precision Vision Camera Inspection System for CSD Plastic Cap Lids |