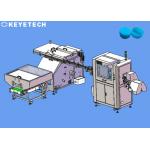

ROPP Bottle Cap Vision Inspection Machine with Online Data Statistics Functions

|

|

ROPP Bottle Cap Vision Inspection Machine with Online Data Statistics Functions Advantages of machine

Inspection principle CCD spring appearance size inspection machine is a new generation of intelligent spring inspection machine developed by a single machine. It is mainly used to replace the manual size inspection and precision inspection of various types of springs. It can automatically complete the inspection and quality identification work at one time, improving the detection accuracy and speed.Greatly improving the detection quality. It is the ideal spring size testing equipment.

Features of system

Cooperation Partners KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

** Our company have served many well-known enterprises such as Coca-Cola, P&G, Unilever, ALPLA, Shriji Polymer, Berry Global, Aptar, LAMIPAK, TPAC, PACT Group, etc.

After-sale service The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation. After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance. |

|||||||

| Product Tags: CCD Camera Product Inspection Equipment OEM Product Inspection Equipment |

|

AI Based Mineral Water Cap Optical Vision Sorting Machine with Feeding Device |

|

SS 304 Vision Inspection Machine Applications Surface Flash, Short Mold, And Black Spot |

|

Dropper Cap Camera Visual Inspection Machine HMI Touch Screen Support |

|

Full Automated AI Dropper Nozzle Plug Vision Inspection Machine |

|

Flip Cap Vision Sorting Machine High Resolution Optical Inspection System |

|

High Precision Vision Camera Inspection System for CSD Plastic Cap Lids |