Juice Bottle Package Inspection Machine Vision Instead Of Human Eyes

|

|

Juice Bottle Package Inspection Machine Vision Instead Of Human Eyes

Inspection standard

Inspection principle Carrot juice is a drink suitable for all ages. The raw materials come from fresh fruits and vegetables. They are rich in various nutrients, such as vitamins, folic acid, calcium, etc.. At the same time, these nutrients are not suitable to be stored for too long. Therefore, many manufacturers understand that carrot juice is a consumable product, and most of them choose recyclable glass and PET containers to hold them. However, in the mass production process of bottle packaging manufacturers, the use of mechanized tools cannot guarantee 100% of the products produced. In fact, the manual detection process cannot guarantee not only the detection speed, but also the accuracy rate. Therefore, professional mechanical equipment and systems are required to carefully detect the finished packaging bottles and the markings on the packaging bottles. Keye Tech has advanced AI vision inspection equipment, which can detect defects that are visible to the human eye with high precision, which greatly improves production and save labor.

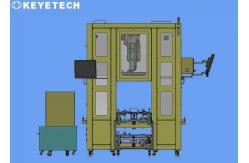

Inspection details Our design plan uses 11 sets of high-pixel industrial cameras and high-performance stroboscopic light sources to carry out comprehensive detection for bottle mouth, bottle bottom and bottle body defects. The whole set of detection equipment includes mechanical parts, visual electronic hardware and detection systems. The software, the entrance and exit of the detection machine can be integrated with the conveyor line, the detection speed is 9600 pieces/hour, the equipment can realize 7*24 hours of operation, and the unqualified products can be automatically rejected.

Main function of system

|

|||||||||||||||||||||||||||||||||||||||||

| Product Tags: Juice Bottle Package Inspection Machine Juice Bottle Package Inspection System |

|

GPU Computing Ai Inspection System For Multi Specification Flip Cap |

|

Edible Oil Bottle Cap Automation Products Closure Optical Sorting Machine |

|

Air Compressed Online Reject Defect Product Water Cap Vision Detection Machine |

|

High Precision 0.1mm Cap Vision Detection System 5kw-7kw Power SS 304 Material |

|

Water Cap Closures Visual Inspection System with 6 CCD Industry Cameras |

|

28mm Closure Inspection Machine with HMI Adapt To National Standard |