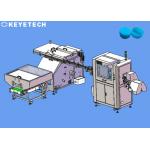

Cap Closures Defect Detect Machine with 360 Degree Camera Inspection

|

|

Cap Closures Defect Detect Machine with 360 Degree Camera Inspection Inspeciton Details

Inspection principle Bottle caps are the most common items in daily life. The bottle caps that I have seen are basically solid colors without any variegated colors, and the size is just right on the bottle. What's going on? Naturally, machine vision inspection equipment is used to check whether the appearance quality of bottle caps is qualified. The more common traditional inspection method is to realize inspection through manual quality inspection. Not to mention the low inspection power, there are often missed inspections, false inspections, etc. When the problem arises, the quality of its detection is difficult to be unified. Bottle cap defect detection requirements The main inspection items include: bottle cap breakage detection, bottle cap height detection, visual inspection of bottle mouth defects, liquid level detection, and bottle label detection. Compared with traditional human eye inspection, machine vision inspection has the advantages of high accuracy, high efficiency, good continuity, inspection and report generation.

Defect solutions Keyi Technology AI image visual inspection, according to product characteristics, customer inspection needs, make customized inspection solutions. Collect, label, and train the optimized model for bottle cap samples before detection, and deploy the model according to the actual needs of customers; during the detection process, through uniform illumination, industrial cameras take pictures and identify its appearance, and the software system classifies and decides on it. Machine vision online detection equipment for the appearance defects of plastic bottle caps, online large-scale, unmanned intelligent visual inspection equipment for the appearance defects of bottle caps, online removal of defective products such as defects and defects, solving the problems of low manual detection power and high outflow rate of defective products The disadvantage is that it improves the work efficiency of appearance inspection and reduces labor, time and management costs.

Our advantages

|

|||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: visual inspection machine automated vision inspection system |

|

AI Based Mineral Water Cap Optical Vision Sorting Machine with Feeding Device |

|

SS 304 Vision Inspection Machine Applications Surface Flash, Short Mold, And Black Spot |

|

Dropper Cap Camera Visual Inspection Machine HMI Touch Screen Support |

|

Full Automated AI Dropper Nozzle Plug Vision Inspection Machine |

|

Flip Cap Vision Sorting Machine High Resolution Optical Inspection System |

|

High Precision Vision Camera Inspection System for CSD Plastic Cap Lids |