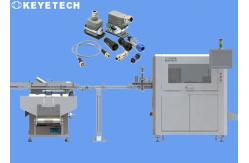

Full Automated Vision Inspection System Widely Used In Rigid Industry

|

|

Full Automated Vision Inspection System Widely Used In Rigid Industry The machine vision system improves the automation of production, makes it possible for dangerous working environments that are not suitable for manual operations, and makes large-scale and continuous production a reality, greatly improving production efficiency and product accuracy. The ability to quickly obtain information and process it automatically also provides convenience for information integration in industrial production. With the maturity and development of machine vision technology, it is not difficult to find that its application scope is more and more extensive. According to these fields, we can roughly summarize the five typical applications of machine vision, and these five typical applications can also basically be summarized. role in industrial production.

1. Image Recognition Application Image recognition is the use of machine vision to process, analyze and understand images to identify targets and objects in various patterns. The most typical application of image recognition in the field of machine vision industry is the recognition of two-dimensional codes. Two-dimensional codes are the most common type of barcodes we usually use. Store a large amount of data information in this small QR code, and track and manage products through the barcode. Through the machine vision system, the barcode on the surface of various materials can be easily identified and read, which greatly improves the efficiency of modern production.

2. Image Detection Application Inspection is one of the most important applications in the machine vision industry. Almost all products need to be inspected. However, there are many disadvantages in manual inspection. The accuracy of manual inspection is low. If you work for a long time, the accuracy cannot be guaranteed. The speed is slow, which easily affects the efficiency of the entire production process.

In addition, it can also be applied to color registration and color comparison inspection in the printing process, printing quality inspection of beverage bottle caps in the packaging process, barcode and character recognition on product packaging, and defect detection of glass bottles. Among them, the defect detection of glass bottles by machine vision system also includes the category of medicinal glass bottles, which means that machine vision also involves the field of medicine. , Bottle inspection, etc.

3. Visual Positioning Application 4. The Object Measurement Application

5. Object sorting application

Our advantages

|

|||||||

| Product Tags: Full Automated Vision Inspection System Modularization Vision Inspection System |

|

GPU Computing Ai Inspection System For Multi Specification Flip Cap |

|

Edible Oil Bottle Cap Automation Products Closure Optical Sorting Machine |

|

Air Compressed Online Reject Defect Product Water Cap Vision Detection Machine |

|

High Precision 0.1mm Cap Vision Detection System 5kw-7kw Power SS 304 Material |

|

Water Cap Closures Visual Inspection System with 6 CCD Industry Cameras |

|

28mm Closure Inspection Machine with HMI Adapt To National Standard |