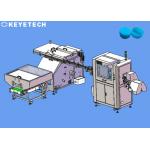

Pull Ring Spout Cap Closures Visual Inspection Machine with Vision Image Processing

|

|

Pull Ring Spout Cap Closures Visual Inspection Machine with Vision Image Processing Inspection Principle The visual inspection machine developed based on machine vision image processing technology has the characteristics of high precision, high speed and multi-sample. The main modules of the system are: trigger positioning module, image processing module and control module. According to user requirements, when the sample moves to the detection position, the camera and the vision system are triggered to output detection signals to complete the detection function. Trigger module: The equipment is automatic feeding. After the

sample arrives at the position, the upper computer equipment

provides a triggering signal (to ensure that the consistency

deviation of the incoming material position is not greater than

1mm). After the visual system software analysis, if the product is

OK, the software interface displays OK , Such as NG products, the

software interface displays NG, and outputs the corresponding test

pass/fail signal. The central disc of the equipment adopts the

photoelectric detection of the diversion device

Main functions of visual inspection

Our advantages

Feeding System The feeding mechanism is docked with the discharge port of the upper mechanism, and the upper mechanism transports the sealing cap to the vibrating plate of the feeding system, and the vibrating plate transports the sealing cap to be inspected to the feeding track according to the preset logic.

Inspection platform When the inspection platform transports the sealing cover to the inspection position, the optical fiber sensor will trigger the camera to take pictures, and the visual inspection system is set according to the inspection index, and the judgment result is given after analysis and operation. When the visual inspection and inspection platform transports the sealing cover to the inspection position, the optical fiber sensor will trigger the camera to take pictures.

Sorting System According to the judgment result of visual inspection and the preset logic switch, the industrial control PLC notifies the solenoid valve to carry out sorting. The sorting action is realized by the blowing nozzle, and the rejected unqualified materials will be respectively stored in the recycling box.

Vision module (camera, lens, light source) The visual inspection system mainly includes: camera, lens, light source and image processing software. After the light source illuminates the sample that reaches the inspection position, the imaging system composed of the camera and the lens captures it. When the camera receives the trigger signal, the imaging system will detect the sample. Take pictures and send the image to the image processing system for identification, judge whether the sample is qualified or not, and output the corresponding OK/NG signal for subsequent equipment processing.

After Sales Service

|

|||||||

| Product Tags: Cap Closures Visual Inspection Machine Vision Image Visual Inspection Machine |

|

Automatic Optical Inspection Machine for Medical Plastic Industry Accessories |

|

Plastic Injection Molded Part Quality Checking Vision Sorting Machine |

|

Professional Vision Supplier Optical Inspection Systems for Pharma Euro Cap |

|

AI Based Mineral Water Cap Optical Vision Sorting Machine with Feeding Device |

|

SS 304 Vision Inspection Machine Applications Surface Flash, Short Mold, And Black Spot |

|

Dropper Cap Camera Visual Inspection Machine HMI Touch Screen Support |