Quality Inspection Machine With CCD Camera Support Different Format Files

|

|

Quality Inspection Machine With CCD Camera Support Different Format Files

As we all know, only advanced machine vision technology solutions can achieve stricter fault detection and quality assurance. KEYE focuses on intelligent equipment such as vision systems, AI artificial intelligence, CCD industrial cameras, and industrial robot applications. Yingtaide visual inspection equipment is widely used and can be used in hardware, plastic products, plastic parts, automotive fasteners, mobile phones, PCB boards, lasers, capacitors, eddy current, artificial intelligence, and other industries. The uses and advantages of visual inspection are mainly reflected in the following aspects:

1. Drive quality and process automation: Through a variety of techniques, devices and algorithms, we use a wealth of machine vision inspection engineering capabilities to maximize the system's potential. Equipment process control and feedback are improved by implementing a well-designed vision system that can increase the data needed to automate most processes. No two vision systems are the same, and our experienced vision engineering technicians are dedicated to providing you with the best solution. We have set up a special department whose responsibility is to design and develop the equipment vision system and inspection equipment hardware structure design required for all our automation systems. No matter what, you can be sure that the system is designed for your project, using the best lighting, optics, cameras and software.

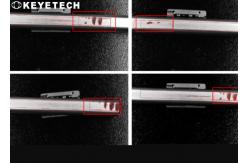

2. Quality inspection: There are 3 types of quality inspections using machine vision systems in our system: defect inspection, tolerance monitoring, dimensional measurement.

3. Process automation: Some equipment vision inspection systems provide customers with feedback data about their product quality and processing capabilities, while others simply assist automated equipment in performing the tasks it was designed to perform. These systems can be extended into three areas: alignment feedback and robotic guidance, part position and orientation, barcode traceability, and print verification.

Our advantages |

|||

| Product Tags: Quality Inspection Machine With CCD Camera ODM Accept Quality Inspection Machine |

|

GPU Computing Ai Inspection System For Multi Specification Flip Cap |

|

Edible Oil Bottle Cap Automation Products Closure Optical Sorting Machine |

|

Air Compressed Online Reject Defect Product Water Cap Vision Detection Machine |

|

High Precision 0.1mm Cap Vision Detection System 5kw-7kw Power SS 304 Material |

|

Water Cap Closures Visual Inspection System with 6 CCD Industry Cameras |

|

28mm Closure Inspection Machine with HMI Adapt To National Standard |