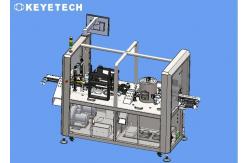

EBI Visual Inspection System Ensure Product Quality with Online NG Rejection

|

|

EBI Visual Inspection System Ensure Product Quality with Online NG Rejection Company Profile Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries. The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

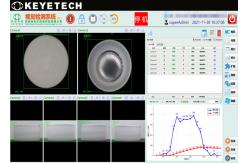

CCD visual inspection details CCD visual inspection and positioning system uses image sensors to replace human eyes, 100% accurate detection of surface defects and defects, and statistics, classification and analysis of defect information, optimization of production process control, classification of products, and classification of qualified and unqualified products. Classify to improve customer trust and satisfaction. CCD machine vision system is a high-tech product used for industrial inspection and identification. The core problem of production is the selection of industrial computer system, which can collect high-definition images of processed products and directly transmit them to the GPIO interface of the machine.

Detection details

Advantages of visual inspection

Cooperation Partners KEYETECH has always been committed to the application of artificial intelligence in the field of vision technology, replacing human eyes and brain decision with machine vision and AI reasoning calculations, and integrating the quality detection and sorting to industrial products in traditional manufacturing to make the production more digitization , Intelligence, visualization, and persistence. Also greatly improves the efficiency and accuracy of industrial detection, and enhances the intelligent level of the manufacturing industry.

** Our company have served many well-known enterprises such as Coca-Cola, P&G, Unilever, ALPLA, Shriji Polymer, Berry Global, Aptar, LAMIPAK, TPAC, PACT Group, etc.

|

||||||||||||||||||||||||||||||||||

| Product Tags: CCD Visual Inspection Systems Metal Embossing Visual Inspection Systems |

|

Plastic Bottle Defect Detection Machine High Performance Vision Inspection System |

|

Bottle Inspection System For Milk Packaging 240 Per Minute OEM Accept |

|

PET Dairy Bottle Inspection System for Food Inspection Station |

|

60mm-90mm Pharma Bottle Visual Inspection System Equipment with image cameras |

|

High Precision Bottle Sorting Machine Visual Inspection System For Soda Packaging |

|

Fanta Beverage Bottle Inspection System High Precision Packaging Vision Systems |