28Mm Water Bottle Caps Closure Visual Inspection System For Beverage Industries

|

|

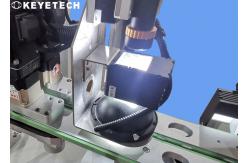

28 Mm Water Bottle Caps Closure Visual Inspection System For Beverage Industries

Product background Visual defect detection system is the mainstream intelligent visual inspection product in industrial production. This type of recognition system is based on computer vision and pattern recognition theory, acquires product images through high-speed high-end industrial cameras, processes and analyzes the images, extracts characteristic parameters reflecting the morphological structure of product varieties, and then uses the characteristic parameters to compare the corresponding Product feature matching, product defect detection, rapid rejection of defective products, and automatic counting of qualified samples, thus greatly improving production efficiency. The bottle cap visual inspection machine can not only be used in dairy products and beverage industries, but also in medicine, daily chemical industry, wine industry, health care products, etc. With its high precision, high speed and comprehensive inspection characteristics, it has become the favor of many production enterprises. Product appearance defect detection equipment.

Inspection principle&features The high-speed bottle cap inspection machine can be equipped with three types of waterfall-type low, medium and high-speed capping machines, which can improve the feeding method of feeding or centrifugal feeding. 360° inspection, which can be applied to the appearance inspection of various and multi-specification plastic covers in dairy products, daily chemicals, medicine, and wine industries. change.

Equipment parameters

Advantage of visual inspection 1)High detection accuracy and fast detection efficiency:CCD visual inspection equipment uses machine control according to the system, with small error and high detection rate. 2)Wide detection range to detect cosmetic defects and dimensional measurements:The multi-station inspection method can accurately measure the outline, specifications, appearance defects, product aspect ratio and other performance parameters of the product to be inspected at one time. 3)Improve product quality and error rates:Vision inspection equipment is based on system control, which can distinguish good products from bad products through automatic inspection technology, and then automatically place them in different parts. 4)Save labor costs and enable high repetitive work:CCD visual inspection can work stably for a long time, it is difficult for human eyes to observe the same object for a long time, and machine vision can perform measurement, analysis and recognition tasks for a long time. And it can continue to work, with low requirements for the natural environment of the application, in addition to saving product costs, it also greatly improves productivity. 5)Improve company competitiveness and employee safety factor:Non-contact detection, which does not cause any damage to observers and observers, improves the reliability of the system. Machine vision technology guarantees the ultimate human-machine interaction technology, which ensures a better and safer workplace. |

|||||||||||||||||||||

| Product Tags: 28Mm Bottle Visual Inspection System Caps Closure Visual Inspection System Beverage Industries Cap Inspection System |

|

GPU Computing Ai Inspection System For Multi Specification Flip Cap |

|

Edible Oil Bottle Cap Automation Products Closure Optical Sorting Machine |

|

Air Compressed Online Reject Defect Product Water Cap Vision Detection Machine |

|

High Precision 0.1mm Cap Vision Detection System 5kw-7kw Power SS 304 Material |

|

Water Cap Closures Visual Inspection System with 6 CCD Industry Cameras |

|

28mm Closure Inspection Machine with HMI Adapt To National Standard |