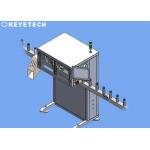

500ml Empty Bottle Inspection System With High Precision Sample Image Showing

|

|

500ml Empty Bottle Inspection System With High Precision Sample Image Showing

Product background In life, people's demand for beverages is essential. Therefore, the appearance of beverage bottles also affects the concerns of every consumer. In order to reduce the number of unqualified beverage bottles, enterprises and manufacturers need to pay attention to the inspection process, and use the appearance defect visual inspection system to detect appearance defects in beverage bottles. Detection can solve this problem very well.

Inspection principle The market demand for mineral water continues to increase, and customers have higher and higher requirements for product quality. Enterprises also pay more attention to brand building. More and more mineral water manufacturers have begun to use bottle cap liquid level coding detection systems. OCR visual inspection of the bottle cap position, liquid level and coding of mineral water bottles replaces the traditional manual inspection, thereby rapidly improving production efficiency and product quality, and solving the low efficiency, slow speed, and missed inspection errors of human inspection. The disadvantages of high detection rate, as well as false detections and missed detections caused by uncertain factors such as the subjectivity of the testing personnel, can achieve better online product testing.

Detection process&system details 1. Install a customized visual inspection system on the mineral water production line; 2. When the mineral water bottle flows into the visual inspection station, the product picture taken by the machine vision sensor is triggered and sent to the system. The system extracts and analyzes the taken picture and compares it with the setting to know whether the bottle cap of the mineral water bottle has a high cap or a low cap. Whether the cover, high and low liquid level, and coding are bad; 3. When it is detected that the mineral water bottle cap has a high cap or a low cap, the coding is defective or the liquid level is high or low, the system sends a signal to the rejection device to give rejection processing and alarm prompts.

Our advantages

------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Anhui Keye Intelligent Technology Co.,Ltd Address:168 Tangkou Road,Taohua Industrial Park,Hefei,Anhui |

|||||||||||||||||||||||||||||||

| Product Tags: 500ml Empty Bottle Inspection System Sample Image Showing Bottle Inspection System 5 Million Pixel Bottle Inspection System |

|

Surface Defective Inspection System Rejection Machine For Juice Bottles |

|

Automatic Defect Detection System Leak Detector For Filling Cocktail Bottles |

|

Impurity Visual Quality Inspection Machine for Cosmetic Bottle Packagings |

|

Plastic Pharmaceutical Bottle Inspection Machine High Accuracy Sorting |

|

Real Time Detection System For Bottle Surface Defects Based On Machine Vision |

|

Real-Time Dairy Empty Bottle Camera Inspection System With Rejection Valve |