Plastic Package Shower Gel Inspection Machine For Bottle Lip Body And Bottom

|

|

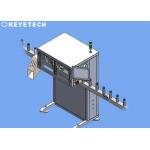

Plastic Package Shower Gel Inspection Machine For Bottle Lip Body And Bottom Shower Gel Inspection Machine For Bottle

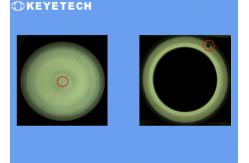

Detection Principle

(1)The transmission part is the core of the system, bearing all the transmission devices and electronic hardware (industrial camera, light source, industrial computer, touch screen, electrical box, etc.). The conveyor belt adopts vacuum adsorption belt to adsorb and fix the sample on the surface of the belt without sliding, so that the photography is accurate.

(2)Transmitted the shooting high-pixel sample image to image processing software by industrial camera, detecting and determining a good product and defective product via AI manually intelligent algorithm.

(3)AI artificial intelligence algorithm to determine the pros and cons of products, to achieve automated production lines ------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- Testing Standards

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- Our Advantages

------------------------------------------------------------------------------------------------------------------------------------------------------------------------- ------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Anhui Keye Intelligent Technology Co.,Ltd Address:168 Tangkou Road,Taohua Industrial Park,Hefei,Anhui |

|||||||||||||||||||||||||||||||

| Product Tags: Shower Gel Inspection Machine Shower Gel Bottle Inspection System |

|

Surface Defective Inspection System Rejection Machine For Juice Bottles |

|

Automatic Defect Detection System Leak Detector For Filling Cocktail Bottles |

|

Impurity Visual Quality Inspection Machine for Cosmetic Bottle Packagings |

|

Plastic Pharmaceutical Bottle Inspection Machine High Accuracy Sorting |

|

Real Time Detection System For Bottle Surface Defects Based On Machine Vision |

|

Real-Time Dairy Empty Bottle Camera Inspection System With Rejection Valve |