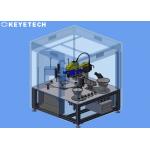

Offline PET Preform Vision Inspection Machine with Material Handling Device

|

|

Offline PET Preform Vision Inspection Machine with Material Handling Device Company Profile Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries. The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

Inspection Principle The defects of PET preforms are mainly caused by defects such as black spots, bubbles, impurities, overlaps, and lack of materials in the production process due to the incomplete production technology and mechanized production line. PET bottle embryos are part of the production of cosmetics. It is mainly processed by injection molding. Before it is made into a finished product, it must undergo strict product appearance detection. Through equipment detection, problems in production can be found in time, and it will play a role in reminding to improve the quality of products and ensure the interests e will open the sample comparison standard, and the production personnel at the customer site can control the comparison accuracy and seleof consumers.

Camera Layout

Software Function

Delivery Time The production cycle of the whole machine is expected to take 9-10 weeks. If additional inspection requirements are added or more adjustment needed, the time will be appropriately extended accordingly. After the equipment arrives at the customer's site, our company arranges after-sales personnel to complete installation and adjustment at the customer's site.

Off-line PET Preform Vision Inspection Machine with Material Handling Device After Sales Service The seller should complete the creation and debugging of the product basic algorithm model before the equipment is shipped, also provide remote assistance after the equipment arrives at the customer site; and provide buyer with the factory data and operation manual of equipment. Daily operation and maintenance services: Our company provides free remote operation and maintenance online services. If you need to upgrade inspection algorithm, provide operational assistance, etc.

Delivery Time The production cycle of the whole machine is expected to take 60 days. If additional inspection requirements are added or more adjustment needed, the time will be appropriately extended accordingly. After the equipment arrives at the customer's site, our company arranges after-sales personnel to complete installation and adjustment at the customer's site. |

||||||||||||||

| Product Tags: Humanized HMI Packaging Inspection Equipment PET Bottle Packaging Inspection Equipment |

|

Top Seal, Body, Injection Gate Inspection and Sorting Machines for PET Preforms |

|

Computer Vision System for Preform Feeding Orientation and Defect Detection |

|

CSD PET Preform Vision Inspection System Optical Camera Checking Machine |

|

AI Based Quality Control Vision Inspection System for Plastic Bottles Preforms |

|

Easy Maintenance and Operation Visual Inspection System For PET Preforms |

|

CCD Visual Defect Inspection Machine for Transparent Colored PET Preform |