ODM Electric Fan Blade Industrial Inspection Systems aoi devices For Defect Detection

|

|

3,Inspection scope

Inspection product description With the popularity of electrical appliances, more and more homes and offices are using electrical equipment. As a component of electrical equipment, the fan blades of electrical appliances play a key role in electrical appliances. The fan blade is a tool for cooling and dissipating heat in electrical appliances. It can protect the electrical appliances during use and prevent wire burnouts and fires caused by overheating.

Inspection scope

General status of the detection system The overall equipment integrates mechanical mechanisms, visual optical hardware and detection system software. The normal detection speed is 4 per minute (because the equipment is dual-channel, this speed is the speed of the two channels together), and the equipment can realize 7*24 hours of operation , Which greatly improves production efficiency.

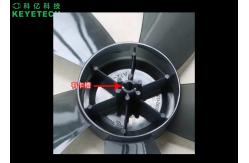

Electric fan blade inspection equipment, with 14 sets of high-pixel industrial cameras, double-station inspection, comprehensive inspection of fan blade appearance defects. After the system collects sample images, the image processing software is compared and analyzed with standardized samples to determine good and defective products. Online alarm for defective products, counting function can be realized after finished product detection, counting accuracy rate is 100%. The software will open the sample comparison standard, and the operator on the customer site can control the comparison accuracy and choose the accuracy standard most suitable for their own production conditions, thereby controlling the defect rate.

Inspection scope 1,The whole set of inspection equipment includes mechanical parts, visual electronic hardware and inspection system software. Both parties need to pre-determine the height of the conveyor line to facilitate the on-site equipment connection. 2,This equipment needs to determine the number of cameras to be used and the corresponding inspection content according to the final requirements of the customer. The following table is for reference only.

5,The testing equipment needs to be regularly maintained and cleaned during use (such as conveyor belt cleaning, camera cleaning, etc.). The testing equipment itself will not cause secondary pollution sources (such as debris, fine foam, etc.) to the tested samples. 6,Equipment schematic image

|

|||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: ODM industrial Inspection Systems aoi Industrial Inspection Systems Industrial aoi devices | |||||||||||||||||||||||||||||||||||||||||||||||||

|

GPU Computing Ai Inspection System For Multi Specification Flip Cap |

|

CCD Camera Cap Sorting Machine With AI Deeping Learning Algorithm |

|

Edible Oil Bottle Cap Automation Products Closure Optical Sorting Machine |

|

Air Compressed Online Reject Defect Product Water Cap Vision Detection Machine |

|

High Precision 0.1mm Cap Vision Detection System 5kw-7kw Power SS 304 Material |

|

Water Cap Closures Visual Inspection System with 6 CCD Industry Cameras |