Visual Inspection System for Plastic Alaska Cap with Machine Vision Technology

|

|

Visual Inspection System for Plastic Alaska Cap with Machine Vision Technology Equipment overviews

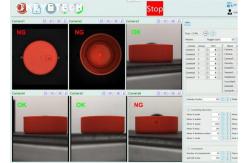

Inspection principle The bottle cap inspection machine adopts machine vision technology to measure, judge and analyze the detected object with the machine instead of the human eye. To a dedicated image processing system, according to pixel distribution, brightness, color and other information, converted into digital signals.

The image system performs various operations on these signals, extracts the characteristics of the target, and then controls the action of the equipment on the spot according to the judgment result of the set standard, and the unqualified products are automatically rejected. In this way, the detection process can realize automatic feeding, automatic detection, automatic sorting, unloading, packing, packing and other system operations, and the detection work is more efficient and fast.

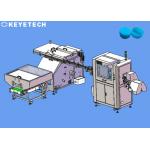

Features of system The AI inspection system integrates lid feeding and handing equipment, conveying mechanism, visual system hardware and inspection software, and defective product rejection device. The maximum inspection speed is about 30,000 pieces/hour, and the equipment can achieve 7*24 It runs 24 hours a day, which greatly improves production efficiency.

The inspection equipment is equipped with a total of 6 sets of high-pixel industrial cameras to comprehensively detect the appearance of defects of the product. After the system collects sample images, the image processing software is compared with standardized samples to determine good and defective products, and the defective products are automatically eliminated online.

Inspection standards

Advantage of system

After Sales Service

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: plastic Waste Sorting Machine cardboard Waste Sorting Machine automatic recycling sorter |

|

AI Based Mineral Water Cap Optical Vision Sorting Machine with Feeding Device |

|

SS 304 Vision Inspection Machine Applications Surface Flash, Short Mold, And Black Spot |

|

Dropper Cap Camera Visual Inspection Machine HMI Touch Screen Support |

|

Full Automated AI Dropper Nozzle Plug Vision Inspection Machine |

|

Flip Cap Vision Sorting Machine High Resolution Optical Inspection System |

|

High Precision Vision Camera Inspection System for CSD Plastic Cap Lids |