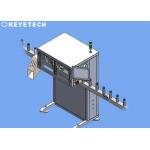

Oil Bottle Visual Inspection System with Data acquisition Module

|

|

Inspection Standard

Inspection Details With the rapid development of industry, bottles can be seen everywhere in daily necessities, such as soy sauce bottles, vinegar bottles, oil bottles, mineral water bottles, etc. They are often of various styles, and there are many brands of the same type of product for consumers to choose from. For consumers, in the face of a variety of products with serious product homogeneity, packaging quality has become an important indicator for consumers to choose products. In the process of consumers choosing products, the experience of product packaging belongs to the first level. However, on the production line, it is inevitable that various defects will appear, and these defects are bound to seriously affect the consumer's evaluation of the product.

Inspection details The whole system adopt 10 sets of high-pixel industrial cameras and high-performance stroboscopic light sources to conduct a full range of visual inspections for the appearance defects of smart cover products. The inspection speed is 300/min. The equipment can realize 7*24 hours of operation. , The unqualified products can be automatically rejected online.

The complete system includes mechanical parts, visual electronic hardware and inspection system software, which can be deployed independently on the customer site for use, and can be connected to the production equipment of the upper and lower processes according to the specific production needs of the customers.

After-sale service The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation. After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

|

|||||||||||||||||||||||||||||||||||

| Product Tags: rubbish Waste Sorting Machine Waste Sorting Machine Sorter Kitchen rubbish sorting machine |

|

Surface Defective Inspection System Rejection Machine For Juice Bottles |

|

Automatic Defect Detection System Leak Detector For Filling Cocktail Bottles |

|

Impurity Visual Quality Inspection Machine for Cosmetic Bottle Packagings |

|

Plastic Pharmaceutical Bottle Inspection Machine High Accuracy Sorting |

|

Real Time Detection System For Bottle Surface Defects Based On Machine Vision |

|

Real-Time Dairy Empty Bottle Camera Inspection System With Rejection Valve |