AI Intelligent Vision Inspection Machine for Bericap Products

|

|

AI Intelligent Vision Inspection Machine for Bericap Products Company Profile Anhui Keye Intelligent Technology Co., Ltd. is a Chinese national high-tech enterprise specializing in the application of AI technology in visual inspection industry. As a leading manufacturer&Designer, It can provide the most advanced level AI visual inspection equipment and the customized AI system solutions of visual imaging, computing power, algorithm, and automatic control software for various sub-industries.

The company was established in 2011, it has a high-level R&D team from top domestic optical research institutes and a core doctoral team from the USTC, covering the entire technology chain of optics, electrics, mechanics, algorithm and software. Our products can be applied in beverage, pharmacy, dairy, wine, textile, new energy, agriculture and other packaging industries.

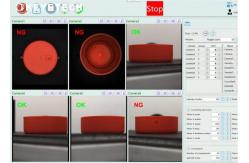

Inspection Theory The product is stably and orderly transmitted to the KEYE cap vision inspection machine, and the high pixel sample images captured are transmitted to image processing software through customized LED light sources and HD industrial cameras. Based on big data, AI algorithms are analyzed and compared, and the system automatically determines defective and good products. The corresponding pneumatic components are controlled to eliminate defective products online, and the good products are counted and boxed to complete product inspection.

The software will open up sample comparison standards, and production personnel at the customer's site can control the comparison accuracy, select the most suitable accuracy standard for their own production situation, and thus control the defect rate. ** The process of inspection system:

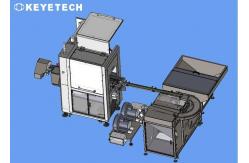

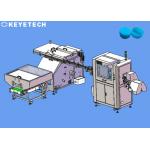

Equipment Overview We adopt 6 sets of high pixel industrial cameras and high-performance LED strobe light sources to conduct comprehensive defect inspection on the appearance of caps. The entire set of detection equipment includes a cap material handling system, mechanical transmission part, optical imaging system, visual electronic hardware, and detection system software. The entire equipment can be independently placed on the customer's site, The maximum detection speed can reach 300-600 pcs/min, the unqualified products can be automatically rejected online and good product can be counted and packed if needed. **Layout of the entire inspection system (for reference only):

Configuration List

Delivery Time The production cycle of the whole machine is expected to take 60 days. If additional inspection requirements are added or more adjustment needed, the time will be appropriately extended accordingly. After the equipment arrives at the customer's site, our company arranges after-sales personnel to complete installation and adjustment at the customer's site.

Others

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Product Tags: Yarn Product Inspection Equipment 60pcs/Min Product Inspection Equipment Yarn automatic fabric inspection machine |

|

AI Based Mineral Water Cap Optical Vision Sorting Machine with Feeding Device |

|

SS 304 Vision Inspection Machine Applications Surface Flash, Short Mold, And Black Spot |

|

Dropper Cap Camera Visual Inspection Machine HMI Touch Screen Support |

|

Full Automated AI Dropper Nozzle Plug Vision Inspection Machine |

|

Flip Cap Vision Sorting Machine High Resolution Optical Inspection System |

|

High Precision Vision Camera Inspection System for CSD Plastic Cap Lids |