1.25L PET Bottle AOI Packaging Inspection Equipment Detection System

|

|

Equipment features:

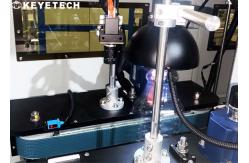

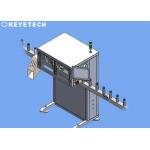

Equipment overview The overall equipment integrates mechanical mechanisms, visual optical hardware and detection system software, defective product rejection and counting devices. The normal detection speed is 150 pieces per minute. The entrance and exit of the detection machine can be integrated with the on-site conveyor line and can be independently matched Leak detectors, balers and other related equipment can be operated 7*24 hours a day, which greatly improves production efficiency. The overall detection equipment, with 10 sets of high-resolution industrial cameras, can comprehensively detect the appearance defects of the outside of the bottle, the mouth and the bottom of the bottle. After the system collects the sample image, the image processing software and the standardized sample are compared and analyzed to determine whether the product is good or not. Good products and defective products will be automatically rejected online. After finished products are detected, the counting function can be realized, and the counting accuracy rate is 100%. The software will open the sample comparison standard, and the production personnel on the customer site can control the comparison accuracy and choose the accuracy standard most suitable for their own production conditions, thereby controlling the defect rate. The overall equipment structure is shown in the figure below:

The detection process is as follows: 1. Detection for the side surface of the bottle body. Considering the characteristics of the bottle body and the height of the bottle body beyond the single-camera viewing angle range, the plan is designed to install cameras on the upper and lower parts, each using 4 sets of industrial cameras, a total of 8 sets of industrial cameras , divided into 2 groups of optical integrating cavity modules, imaging does not interfere with each other, the acquisition angle range of each camera is shown in the figure above. 2. Detection for the outer bottom surface of the bottle. Use the clamping mechanism to suspend the outer bottom of the bottle, and install 1 set of industrial cameras underneath, and use it with the visual light source to collect the image of the outer bottom for processing. 3. Detection of the bottle mouth area. 1 set of industrial cameras are installed on the top of the bottle body to use with the visual light source to collect images of the inner side of the bottle mouth for processing. Detecting content: The problem of bottle mouth: 1. Bottle mouth lack of glue ≥ 0.3mm 2. Bottle mouth defect, knock damage ≥ 0.3mm 3. Bottle mouth deformation ≥ 0.3mm

The problem of the bottle body: 1. The bottle body is whitish: visible under natural light 2. The bottle body is obviously scratched (not fixed position) ≥2*2mm 3. Black spots, impurities on the bottle body≥ 0.3mm 4. The bottle body is sunken (compression mold, not fixed position) ≥2*2mm 5. The bottle body is hazy and opaque: visible under natural light

Problems with the appearance of the handle: 1. Lack of glue on the handle ≥ 0.3mm 2. Handle defect ≥ 0.3mm 3. The outside under the handle is not fully blown 4. The inside under the handle is not fully blown 5. The top of the handle is not fully blown 6. Blowing crooked under the handle |

|||||||

| Product Tags: 1.25L Bottle Packaging Inspection Equipment AOI Packaging Inspection Equipment Bottle aoi inspection equipment |

|

Surface Defective Inspection System Rejection Machine For Juice Bottles |

|

Automatic Defect Detection System Leak Detector For Filling Cocktail Bottles |

|

Impurity Visual Quality Inspection Machine for Cosmetic Bottle Packagings |

|

Plastic Pharmaceutical Bottle Inspection Machine High Accuracy Sorting |

|

Real Time Detection System For Bottle Surface Defects Based On Machine Vision |

|

Real-Time Dairy Empty Bottle Camera Inspection System With Rejection Valve |