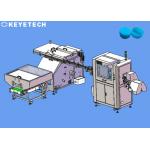

Rigid Plastic Packaging Pop-Top Closure Flip Cap Visual Inspection Machine

|

|

Rigid Plastic Packaging Pop-Top Closure Flip Cap Visual Inspection Machine

Inspection principle Pour the bottle cap with a diameter of 5`6mm into the cap arrange equipment through the conveying line transport it stably and orderly through the photographing area of the industrial camera, and transfer the captured high-pixel sample image to the image processing software for comparison and analysis with the standardized model. After comparative analysis, it is determined whether the concave surface of the bottle cap, the trademark surface, and the side are defective, and the defective products are eliminated by compressed air, and the qualified products are finally collected. After the finished product is tested, the counting function can be realized, the counting accuracy rate is 100%, and the equipment can realize 7*24 hours all-weather operation.

Inspection details The system is equipped with 6 sets of 230W pixel black-and-white industrial cameras, a cap sorting machine, and a full range of defect detection on the concave surface, trademark surface and side of the bottle cap. The normal detection speed is 1000 pieces per minute; the machine first completes the concave surface and The defect detection function in the side range, and then the vacuum adsorption method is used to adsorb and transport the product for defect detection on the trademark surface, which greatly improves the efficiency.

The standards are as follows:

Function of the inspection software

Reference pic of the sample

The pharmaceutical industry has fully realized the importance of good packaging design to increase brand life and attractiveness. The industry believes that pharmaceutical companies must innovate and improve efficiency to cope with the growing threat of counterfeit drugs. Therefore, pharmaceutical companies will have an increasing demand for the pharmaceutical packaging market. |

||||||||||||||||||||||||||||||||

| Product Tags: 6mm Cap Visual Inspection System 9mm Cap Visual Inspection System pharmaceutical visual inspection machine | ||||||||||||||||||||||||||||||||

|

Automatic Optical Inspection Machine for Medical Plastic Industry Accessories |

|

Plastic Injection Molded Part Quality Checking Vision Sorting Machine |

|

Professional Vision Supplier Optical Inspection Systems for Pharma Euro Cap |

|

AI Based Mineral Water Cap Optical Vision Sorting Machine with Feeding Device |

|

SS 304 Vision Inspection Machine Applications Surface Flash, Short Mold, And Black Spot |

|

Dropper Cap Camera Visual Inspection Machine HMI Touch Screen Support |