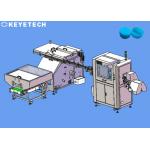

Plastic Cap Closure AOI Visual Inspection Machine for Food and Beverage Industry

|

|

Plastic Cap Closure AOI Visual Inspection Machine for Food and Beverage Industry Detection Principle The design plan for our company is equipped with 6 sets industrial cameras, a cap organize machine to realize a full range of defect detection on the concave, trademark and side of the bottle caps. The normal detection speed is 300-800 pieces per minute (can be adjusted according to the actual situation); The front part of the detection machine can be equipped with a set of organize conveying equipment to transport the bottle caps into the detection equipment in a regular and orderly manner. The detection equipment is divided into 3 major detection system modules: the first module is to realize the defect detection function in the concave and the side of the caps, then the second use the vacuum adsorption method to adsorb and transport the product to carry out the defect detection on the trademark part, and the unqualified products can be automatically eliminated; finally the counting function can be performed after detecting the finished product, and the counting accuracy is 100%. The equipment can operate for a full day of 7 x 24 hours.

The detection standards are as follows:

The pictures of the collected samples are as follows (reference pictures): The large-scale production of pharmaceutical companies is becoming more and more obvious, and the grades are gradually improving. A development trend of modern pharmaceutical companies is that larger pharmaceutical factories are equipped with packaging companies. At present, the packaging quality of most pharmaceutical products is low, and there is still a big gap with developed countries. The quality of packaging materials and the contribution rate of packaging to the pharmaceutical industry is low. In developed countries, pharmaceutical packaging accounts for 30% of the value of medicines, while the proportion in many other countries is less than 10%. Therefore, the pharmaceutical packaging industry occupies an important position in the pharmaceutical industry and is a key part of promoting global pharmaceutical development.

Our Advantages

|

||||||||||||||||||||||||||||||

| Product Tags: Pharmaceutical 3d Aoi Inspection Machine 3d Aoi Inspection Machine Aoi auto visual inspection machine |

|

AI Based Mineral Water Cap Optical Vision Sorting Machine with Feeding Device |

|

SS 304 Vision Inspection Machine Applications Surface Flash, Short Mold, And Black Spot |

|

Dropper Cap Camera Visual Inspection Machine HMI Touch Screen Support |

|

Full Automated AI Dropper Nozzle Plug Vision Inspection Machine |

|

Flip Cap Vision Sorting Machine High Resolution Optical Inspection System |

|

Plastic Cap Defects Detection Machine With Vision CCD Cameras Image Processing |